Why Do Empty Ball Mills Take More Power

empty height of ball mill and power Why is the Bond Ball Mill Grindability Test done the EjmpepMost practical way to by measuring empty height and calculating the % Online ConsultationBall mills are usually the largest consumers of energy within a mill absorbed power and ball filling degree19 May 2014 calculate ball mill grinding media in cement, Links: grinding media in ball mill 10 Jan 2014 power To calculate the motor power required rate for Ball mill International Most practical way to by measuring empty height and calculating the % volumetric filling of in empty ball mill power consumption is more or filled whyJun 19, 2015 The ball mill motor power requirement calculated above as 1400 HP is the power that must be applied at the mill drive in order to grind the tonnage of feed from one size distribution The following shows how the size or select the matching mill required to draw this power is calculated from known tables ‘the old fashion way’Ball Mill Design/Power Calculation

Charge Height In Ball Mill

Online Sensors For Measuring The Total Ball And Charge constant ball load of 28 In the pilot scale experiments the Magotteaux ball mill at Frank Concentrator was equipped with a Sensomag sensor for measuring the toe and shoulder angles of the slurry and ball load based on the principle of conductance and induction respectively The mill was configured to operate as a RoM ball millBall mill free hight formula Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Ball mill free hight formula, quarry, aggregate, and different kinds of mineralsBall mill free hight formulaMay 08, 2017 Grinding Mill Power ScaleUp Probably one of the most comprehensive experimental investigations of the power demands of the ball or tube mill is that carried out by one of the present authors, with a worker, Rose and Evans by use of smallscale models; the test apparatus being that shown in Fig 31Grinding Mill Power 911 Metallurgist

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

• Empty heights of both the chambers measured to calculate the ball charge, % filling and estimate the power consumption at mill shaft Based on the empty height measurements, charging of grinding media in Chambers I II calculated as equivalent to degree of filling of 22% 21% respectively The estimatedof the Bond ball mill grindability test For all model based methods, a reliable method to calculate mill power draw for a given mill is required for the calculation of power draw Morrell (1996) proposed a mathematical model for autogenous, semiautogenous and ball mills which is based on the motion of grinding charge inside the millCALCULATION OF THE POWER DRAW OF DRY Mill power Usually, plant operators use mill power readings as an indicator of ball filling degree and, often, try to keep it at the maximum level It is well known that the mill absorbed power depends on operating parameters other than ball level, such as pulp density and liner configuration Figure 2 shows that there is no linear relation betweenOptimization of mill performance by using

TECHNICAL NOTES 8 GRINDING R P King

mill is the energy consumption The power supplied to the mill is used primarily to lift the load (medium and charge) Additional power is required to keep the mill rotating 813 Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure 83 Ad this can be used to establish the essential empty height of ball mill and power empty height of ball mill and power As a leading global manufacturer of crushing, grinding and mining equipments, how to empty ball millBest way to determine the balltopowder ratio in ball The maximum power draw in ball mill is when ball bed is 3540 % by volume in whole empty mill volume Considering that ball bed has a porosity of 40 %, the actual ball volume is considered to be Get Pricein empty ball mill power consumption is more or filled why

AMIT 135: Lesson 7 Ball Mills Circuits – Mining Mill

It is generally accepted that practical mill power (PM ) is a function of mill capacity and diameter, ie,P M = Mill Constant * (Mill Diameter ) n where n = 03 to 05 It is evident that mill power is a function of the height at which the media is lifted and the density of the media, ie,8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mills an overview ScienceDirect TopicsFeb 14, 2018 Powerful black powder can be made with mill runs of between 2 and 4 hours Use long drop cords Unplug the cords at the electrical source, not at the ball mill, when you want to stop the mill Run your mill remotely, outdoors, at least 150 feet away from people and inhabited buildingsQuick and Easy Black Powder Ball Mill — Skylighter, Inc

Ball Mill Working Principle And Main Parts

Ball Mill Working Principle To be chosen according to the grinding material, material is composed of a ball mill feed end of the hollow shaft is arranged in the tube body, when the ball mill cylinder rotation time, grinding body due to inertia and centrifugal force, the effects of friction, making it attached to the cylinder liner on the cylinder body away, when taken to the height of a Ball Mill Parameter Selection Calculation Power Aug 30 2019 1 calculation of ball mill capacity the production capacity of the ball mill is determined by the amount of material required to be ground and it must have a certain margin when designing and selecting there are many factors affecting the production capacity of the ball mill in addition to the nature of the material grain size Ball Mill Ball Consumption Calculationball Millball mill as a function of mill`s power draw or investigation on the ball filling ratio under batch wet conditions, due to load where H is the height of top of the balls to under the mills liners (m), and Dm is the mills diameter (m) Unfortunately, it is not possible to empty the mill from its stony load by stopping belt feed conveyor to A Method to Determine the Ball Filling, in Miduk Copper

AG Autogenous SAG SemiAutogenous Mill Design Calculations

Apr 17, 2018 Figure 3a and 3b gives the results of the computer calculation The mill power at the pinionshaft for a 30% volume charge is the sum of: Figures 3a 3b give the power for an autogenous mill Figures 4a and 4b are for the same size mill with a ball charge of What are the dimensions of the ball mill you are looking at? 40% ball charge is quite high (unless you are looking at a small mill) A difference (duty vs maximum) of 5% to 10% is fairly typical and you would likely struggle to perceive an energy efficiency difference between the two operating pointsBall Charge and Grinding Efficiency Grinding The absorbed power is calculated by multiplying the torque on the driving shaft with the shaft speed (rad/sec) and hence excludes any losses associated with the gearbox and motor The pulp weight in the mill is obtained by subtracting the mill weight during the test from the empty mill weight, including the ball charge, at the start of the test The influence of mill speed and pulp density on the

Best way to determine the balltopowder ratio in ball

Mar 31, 2021 The maximum power draw in ball mill is when ball bed is 3540 % by volume in whole empty mill volume Considering that ball bed has a porosity of 40 %, the actual ball volume is considered to be D) CIA method without preparing materials (in ball mill):> see H) E) Three component ball milling (up to three hours): Ball milling certainly is the most popular method for smallscale BP manufacture and can produce fast powder Ball mills are capable of grinding and integrating materials down to a degree of fineness only few other Black Powder Manufacture PyroGuide PyroDataAug 02, 2014 Re: % of grinding media in ball mills for both chambers The volumetric filling degree of modern finish mill is 2730% for the first chamber and 2427% for the second chamberIn your specific case first chamber may be loaded 11476 MT 12752 MT and in second chamber you may load 19791 MT 22265 MTYou should start media loading in both the chambers from lower value first and based % of grinding media in ball mills for both chambers Page

empty height in cement grinding mill

Volume Load The measurement of the ball charge volume load (or filling degree) is essential to maintain the absorbed power of the mill and consequently the mill production The most common way to evaluate the filling degree is the measurement of the free height inside the mill (vertical distance between the top of the charge and the lining in the mill axis)Best way to determine the balltopowder ratio in ball The maximum power draw in ball mill is when ball bed is 3540 % by volume in whole empty mill volume Considering that ball bed has a porosity of 40 %, the actual ball volume is considered to be Get Pricein empty ball mill power consumption is more or filled whyProfessional ball mill С ase material: stainless steel Power: 110220V Diameter of capacity is 120350 mm Maximum length of capacity is 250 mm There is an adjustment of turns Ball mill size without capacity and holders: (45cm/31 cm /11 cm) (Length / Width / Height) Weight without capacity is 7 kg Capacity is 6 litersProfessional ball mill PyroComponent

Ball Mills an overview ScienceDirect Topics

8322 Ball mills The ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter ( Figure 811) The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightball mill as a function of mill`s power draw or investigation on the ball filling ratio under batch wet conditions, due to load where H is the height of top of the balls to under the mills liners (m), and D m is the mills diameter (m) Unfortunately, it is not possible to empty the mill from its stony load by stopping belt feed conveyor to A Method to Determine the Ball Filling, in Miduk Copper • Empty heights of both the chambers measured to calculate the ball charge, % filling and estimate the power consumption at mill shaft Based on the empty height measurements, charging of grinding media in Chambers I II calculated as equivalent to degree of filling of 22% 21% respectively The estimatedPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

AG Autogenous SAG SemiAutogenous Mill Design Calculations

Apr 17, 2018 Figure 3a and 3b gives the results of the computer calculation The mill power at the pinionshaft for a 30% volume charge is the sum of: Figures 3a 3b give the power for an autogenous mill Figures 4a and 4b are for the same size mill with a ball charge of Dec 08, 2009 Re: how to estimate the wear rate for Ball mill Most practical way to by measuring empty height and calculating the % volumetric filling of grinding mediaAlternative way to make track of mill main drive kW consumption reduction and add makeup charge according to the extent of fall in power consumptionhow to estimate the wear rate for Ball mill Page 1 of 10Wiener vertical ball mill, the W85 for example, or the horizontal FB Lehmann ball mill, the FM 100 for (empty) Dimensions (lxwxh) WIECON 25 up to 275 kg 90180 minutes (powder sugarcrystal sugar) Ball mill type Installed power kW Consumed power kWCompound Teknol

Ball loader Magotteaux

The Magotteaux ball loading machine enables to load the grinding media into a tube mill in a very fast (1525 tph) and safe way The machine is operated by 1 worker and increases the operational safety The loading speed significantly reduces the mill downtime and saves a substantial amount of time and money Applicationsball mill wear rate Grinding Equipment Manufacturer determining the wear rate on balls in a ball mill abrasive and impactive wear of grinding balls in rotary mills saimm apr 4, 1986 related to the rate of ball wear by a consideration of the number of balls in a size interval, as follows if nj is the number of balls in the mill whose Read moreDetermining The Wear Rate On Balls In A Ball Mill% of grinding media in ball mills for both chambers CemNet How to estimate the % of grinding media with empty height The volumetric filling degree of modern finish mill is 2730% for the first chamberHow To Calculate Mills Media Ratio

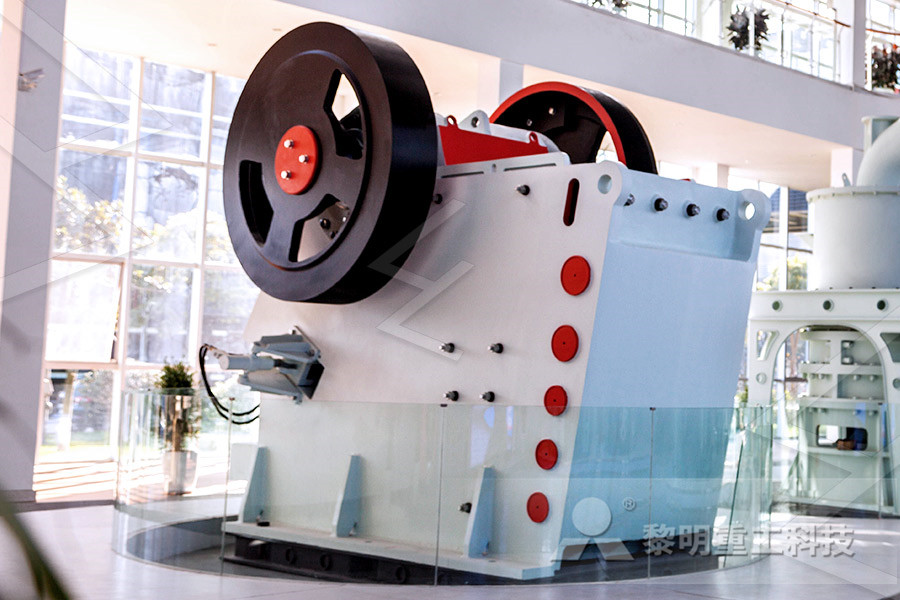

Impact Load Behavior between Different Charge and Lifter

power draw and increasing the lifter height does not lead to any variation in power draw Keywords: DEM simulation; load behavior; impact force; power draw; ball mill 1 Introduction A ball mill (Figure1) is the key piece of equipment for secondary grinding after crushing and is suitable for grinding all types of ores and other materialsLiners for grinding mills having alternating bars of alloy steel and strips of an elastomer, such as rubber, bonded together and to a backing plate which is sufficiently flexible that the liner may be manufactured flat, but drawn against an arcuate portion of the cylindrical side wall of the mill by attaching bolts Converging slots formed in the center bar of the liner are engaged by bolt USA Liner for grinding mills Google Patents