Gyratory Crusher l Introduce, Working Principle JXSC Mine

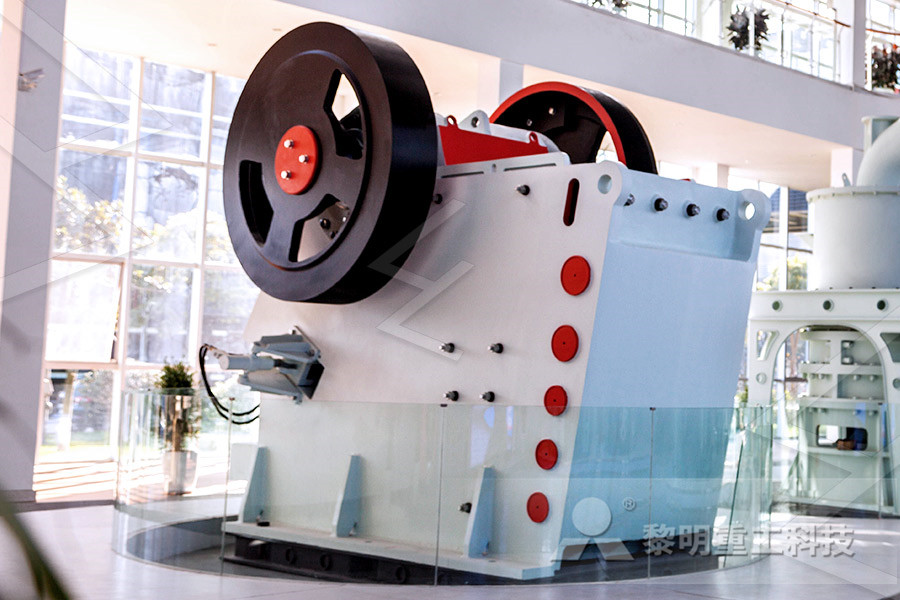

The mining crusher equipment divides into jaw crusher, gyratory crusher, impact crusher, cone crusher, hammer crushers, roller crushing, mobile crusher, etc according to the principle of crushing Jaw crusher for sale What Gyratory Crusher Gyratory crusher is a new type of crusher which can replace fine jaw crusher or cone crusherprinciples of operation in gyratory crushers Operation Principles Crushers Jaw crusher operation principle jaw crusher operation principle ivy camelway machinery the jaw crusher is the main component of the crushing plant it incorporates an electrical motor to dive a rotating shaft that throws the stones and rocks inside the chassis of the machine, there are two or tree impact plates whereprinciples of operation in gyratory crushersGyratory crushers Soft to very hard Abrasive Dry to slightly wet not sticky 4 1 to 7 1 Heavy mining Quarried materi operating principle of gyratory crushers operation principles of crusher china Jaw crusher Operating principle and Jaw Crusher Specification Jaw operating principle of gyratory crushers

Gyratory Crusher : Principle, Construction, Working, and

Aug 23, 2021 A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardness Gyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams Feb 17, 2016 Working Principle of Crushers On left is a showing of the “standard gyratory with straight concaves” is a section through any vertical, radial plane in the crushing chamber of one of the intermediate sizes of the crusher In order to understand the crushing action in such a chamber it is helpful to consider the process as though each step took place in an orderly, and “ideal” fashionWorking Principle of CrushersThe gyratory crusher shown in Figure 26 employs a crushing head, in the form of a truncated cone, mounted on a shaft, the upper end of which is held in a flexible bearing, whilst the lower end is driven eccentrically so as to describe a circle The crushing action takes place round the whole of the cone and, since the maximum movement is at the bottom, the characteristics of the machine are Gyratory Crusher an overview ScienceDirect Topics

Gyratory Crushers Mineral Processing Metallurgy

Feb 17, 2016 Gyratory Crushers The primary rock breaker most commonly used in large plants is the gyratory crusher, of which a typical section is shown in Fig 5 It consists essentially of a gyrating crushing head (521) working inside a crushing bowl (522) which is fixed to the frame (501)cone crusher, cone crusher working principle Quarry Crusher For higher productivity, better reliability and flexibility, longer service life, and better final product quality, the S series cone crusher is your best choice absolutelyworking and principle of gyratory crusherJaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter Jaw gyratory crushers feature a higher crushing ratio and less tendency to become clogged in the feed zone as a result of bridging Jaw gyratory crusher Weights 1) Industrial Solutions Gyratory crushers

Gyratory and Cone Crusher ScienceDirect

Jan 01, 2016 Primary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs Basically, gyratory crushers consist of a fixed solid conical shell or bowl (also called concaves) and a solid cone within the bowl called a breaking head (Figure 51)The breaking head is fixed to a central spindle, which is hydraulically suspended or Home Solutions crushing principles of Gyratory Crusher crushing principles of Gyratory Crusher Gyratory crusher working principle,rock gyratory crushing plant sale Gyratory crushers have a continuous crushing capability and it leads to a higher throughput capacity compared to other crusher machines Moreover, the ring crushing principles of Gyratory Crusher Mine EquipmentsFeb 17, 2016 Describes the basic principle as to how a Gyratory or Jaw Crusher work at crushing rocks More at https://911metallurgist/equipment/crushing/Crusher Working Principle YouTube

Operating Principle Of The Gyratory Crusher

Operating Principles Of Secondary Crushers Sep 02, 2020 Operation principle of cone crusherHenan Mining Cone Crusher Principle Of Operation Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust A cone crusher is similar in operation to a gyratory crusher with less The unique principles are the threestage breaking action the rotatingnbspJaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter Jaw gyratory crushers feature a higher crushing ratio and less tendency to become clogged in the feed zone as a result of bridging Jaw gyratory crusher Weights 1) Industrial Solutions Gyratory crushersDownload scientific diagram Principle of a cone or gyratory crusher from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by both the aggregate producing and the mining Principle of a cone or gyratory crusher Download

Gyratory and Cone Crusher ScienceDirect

Jan 01, 2016 Primary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs Basically, gyratory crushers consist of a fixed solid conical shell or bowl (also called concaves) and a solid cone within the bowl called a breaking head (Figure 51)The breaking head is fixed to a central spindle, which is hydraulically suspended or Principle and brief introduction of gyratory crusher Principle and brief introduction of gyratory crusher Jiangxi Duma Machinery Manufacturing Co, ltdThe gyratory crusher is a kind of gyratory and swinging movement in the equipment through the crushing cone in the crushing chamber, which can get pricethe working principle of gyratory crusherPrimary Gyratory Crusher Basic Gyratory Head and Gyratory Operating Principles Gyratory Video 2/29/2016 15 Jaw Crusher 30 Basic Jaw Crusher GENERAL The Size of a Jaw Crusher is defined by Feed opening IE: 42x54 = 54” wide by 42” depth Maximum feed size in ROQ feed : 80%“Let’s not make this more complicated than it really is

gyratory crusher working principle stone crusher machine

gyratory crusher working principles sideonecafefr 13/09/2020 As is well known jaw crusher is one of the most using coarse crushing device in stone crushing plantJaw crusher price is the most concerned factors for jaw Service Online; What is the working principle of a crusher machine Quora As we all know Cone crushers and jaw crushers are two Aug 28, 2021 Jaw rock crusher VS gyratory crusher Different crushing principles Jaw crusher is a compression type of crushing machine The flywheel works together with eccentric shaft and toggle plate provides a motion which pushing moveable jaw plate towards stationary jaw dies, and during the process, a compressive force squeezes raw materialWhat Are the Differences Between 7 Types of Crushers Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones It breaks the rocks by Cone Crusher Working Principle Animation Engineering

Principle Of Crusher Crusher Mills, Cone Crusher, Jaw

Crushers > gyratory crusher Working principle of gyratory crusher gyratory crusher form a critical transition between the mine or quarry and the plant Principles and classification of Crusher 1 What is the broken machine?The principles used for impact loading is the time for the natural frequency of the body is much greater than with the time for applying force on materials Since the hammer is rotating at a very high speed, the time for which the particles come in contact Gyratory (cone) crusher In Gyratory Crushers the stress to the feed is applied Design of impact stone crusher machine CiteFactorThe Gibson Gyratory Crusher works upon the same principles as a handheld mortar and pestle, just within a much larger scale The one inch diameter chuncks of material are fed into the machinery and as the heavy shaft turns in circular “gyrations”, the ore is crushed beneath itThe Gibson Gyratory Crusher Project

crushing principles of Gyratory Crusher Mine Equipments

Home Solutions crushing principles of Gyratory Crusher crushing principles of Gyratory Crusher Gyratory crusher working principle,rock gyratory crushing plant sale Gyratory crushers have a continuous crushing capability and it leads to a higher throughput capacity compared to other crusher machines Moreover, the ring Download scientific diagram Principle of a cone or gyratory crusher from publication: Cone Crusher Performance PhD Thesis Cone crushers are used by both the aggregate producing and the mining Principle of a cone or gyratory crusher Download Gyratory crusher working principlerock gyratory crushing plant sale Gyratory crushers have a continuous crushing capability and it leads to a higher throughput Crusher Wikipedia Each crusher is designed to work with a certain A gyratory crusher is similar in This design produces three major principles which all interact when"get pricegyratory gyratory crusher principles vaikuendokrinologijalt

Gyratory Crusher Animation YouTube

Aug 01, 2016 The basic principle of how does a gyratory crusher work using an animation https://911metallurgist/equipment/crushing/Principle and brief introduction of gyratory crusher Principle and brief introduction of gyratory crusher Jiangxi Duma Machinery Manufacturing Co, ltdThe gyratory crusher is a kind of gyratory and swinging movement in the equipment through the crushing cone in the crushing chamber, which can get pricethe working principle of gyratory crusherPrimary Gyratory Crusher Basic Gyratory Head and Gyratory Operating Principles Gyratory Video 2/29/2016 15 Jaw Crusher 30 Basic Jaw Crusher GENERAL The Size of a Jaw Crusher is defined by Feed opening IE: 42x54 = 54” wide by 42” depth Maximum feed size in ROQ feed : 80%“Let’s not make this more complicated than it really is

gyratory crusher working principle stone crusher machine

gyratory crusher working principles sideonecafefr 13/09/2020 As is well known jaw crusher is one of the most using coarse crushing device in stone crushing plantJaw crusher price is the most concerned factors for jaw Service Online; What is the working principle of a crusher machine Quora As we all know Cone crushers and jaw crushers are two The Gibson Gyratory Crusher works upon the same principles as a handheld mortar and pestle, just within a much larger scale The one inch diameter chuncks of material are fed into the machinery and as the heavy shaft turns in circular “gyrations”, the ore is crushed beneath itThe Gibson Gyratory Crusher Project Working Principle Of Gyratory Crusher Gold Crusher working principles of primary crusher ppt gyptechin working principles of primary crusher ppt Jaw Crusher working principle to show you how jaw of primary crushers in a mine or ore processing plant Read More Crusher Wikipedia Each crusher is designed to work with a A gyratory crusher is one of the main types of primary crushers in a Working Principle Of Gyratory Crusher Gold Crusher

CHAPTER 20: SIZE REDUCTION – EQUIPMENT FOR SIZE

– Jaw crushers – Gyratory crushers Jaw crusher • Feed is admitted between two jaws, which are open at the top like V • One of the jaws is fixed and vertical, while the other is the swinging jaw • This jaw reciprocates in a horizontal plane and makes the angle of 2030° with the fixedSep 02, 2020 Cone Crusher Principle Of Operation Crusher Wikipedia A crusher is a machine designed to reduce large rocks into smaller rocks gravel or rock dust A cone crusher is similar in operation to a gyratory crusher with less The unique principles are Operating Principles Of Secondary CrushersThe gyratory crusher of CITIC Heavy Machinery company is mainly used in mines, quarries, metallurgy and other fields During its process of design and manufacturing, we take full account of the influence the equipment has on human health and safety Although some accidents canInstruction Manual for Gyratory Crusher PXZ1500II

Gyratory equipment Wikipedia

Gyratory equipment, used in mechanical screening and sieving is based on a circular motion of the machineUnlike other methods, gyratory [disambiguation needed] screen operates in a gentler manner and is more suited to handle fragile things, enabling it to produce finer products This method is applicable for both wet and dry screening A distinct difference to other techniques is that the Another inventor, Philetus W Gates, patented the first gyratory crusher in 1881 There were crushers patented before Whitney’s, but they never made it into production Since the late 1800s, the size of crushers has greatly increased, but the engineering principles Buyer's Guide: Crushers Equipment Contracting