BALL MILL MAINTENANCE The Cement Institute

CEMENT RELIABILITY MAINTENANCE SEMINAR; CRUSHING AND GRINDING MILL SEMINAR The Ball Mill Maintenance course is designed to engage in the effective use of handson learning methodology as a unique combination of theory and practical work section applied to the ball mill system’s maintenance inspection operation, and maintenance Ball Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill systemsOperations and maintenance training for ball millsJul 29, 2013 Ball Mill Operations and Maintenance Having skilled team plays a key role in the optimal utilization of the grinding installation in the cement plant The operators and process engineers must be able to evaluate all the process variables in order to optimize the production economyBall Mill Operations and Maintenance Training Center

Ball Mill Operation And Maintenance

Ball Mill Maintenance Installation Procedure 19/10/2016 Ball Mill Maintenance Manual The purpose of this manual is to assist you in the proper installation and to acquaint you a bit further with the assembly and care of this equipment We suggest that these instructions be read carefully and reviewed by everyone whenever involved in the actual installation and operation of the mill In reading Operations and maintenance training for ball mills Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill How to do the Ball Mill Repair Ball Mill Maintenance In Mine PlantOperations and maintenance training for ball mills Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill Ball Mills Mineral Processing ball mill capacity tph maintenance and trouble shooting

Ball Mill Maintenance Installation Procedure

Oct 19, 2016 Ball Mill Maintenance Manual The purpose of this manual is to assist you in the proper installation and to acquaint you a bit further with the assembly and care of this equipment We suggest that these instructions be read carefully and reviewed by everyone whenever involved in the actual installation and operation of the millFeb 17, 2014 Ball Mill Maintenance 1 – 3 April 2014 Mill maintenance and mill repair are two crucial factors in ensuring production efficiency – and this seminar will present best practices within the maintenance of the ball mill and the auxiliary equipment More information: Link to brochure Pyro Process – Operations and Process Simulation Seminar Upcoming seminars in the USA Ball Mill Manual Pdf Maintenance training and safety equipment operation/maintenance program projects on plant maintenance pdf free download – Gold Ore Navision Plant Maintenance – Related DocumentsMaintenance Program Crushers Pdf Crusher Mills, Cone

Raymond Mill Operation Manual Crusher Mills, Cone

Raymond Mill Maintenance – liming,Crusher,Grinding Mill,Ball 2) To ensure normal operation of the equipment, a manual containing strict rules and procedures for its operation, Raymond Mill operation process: Oct 17, 2016 The Ball Mill operation and maintenance seminar will offer the participants the ability to be trained on the mill technology and components More ballmill operation and maintainanceJul 29, 2013 Ball Mill Operations and Maintenance Having skilled team plays a key role in the optimal utilization of the grinding installation in the cement plant The operators and process engineers must be able to evaluate all the process variables in order to optimize the production economyBall Mill Operations and Maintenance Training Center

I Ball mill maintenance Fathom Engineering

GEARS DRIVE TECHNOLOGY I Ball mill maintenance by Dr Devinder S Grewal, PE, Cement plant operators often have to make decisions about repair or Principia Engineering Inc, USA replacement of older equipmentOlder equipment, that is suffering from ME068: Ball Mill Operations and Maintenance This ball mill training course is designed to train each participant on the overall technology, operation and maintenance of the ball mill cement grinding system The training course focuses on the latest best practices for the operation and maintenance of ball mill systems to allow for optimal cement production, energy savings, reduced maintenance ball mill maintenance courseBall mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance preventive and reactive to achieve energy savings reduced maintenance costs and overall improved productivity of the ball mill systemstraining to ball mill motors

Ball Mill Maintenance In Mine Plant

Operations and maintenance training for ball mills Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill How to do the Ball Mill Repair Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5 day training seminar focused on best practices for operations and maintenance preventive and reactive to achieve energy savings reduced maintenance costs method for maintenance of ball millInstallation, Operation, and Maintenance Manual 2 CamTite Ball Valve Installation, Operation, and Maintenance Manual Instruction and training can be carried out by either ITT or the reseller of the valve by order of the operating companyRoller Mill Maintenance CPM, aspects, maintenance and operation of the equipment is remarkably similar Roller mill maintenance can be broken down into three operation and maintenance manual ball mill

Hierarchical framework for maintenance and production

In the scheduling horizon, two types of maintenance operations are necessary for ball mills 1 and 2 whereas for ball mill 3 only the first type is required Only one maintenance technician is available at periods 17 to 24 and 41 to 48, while there are two technicians in other periods 18 slurry orders must be processed during the scheduling Specific applicable Whether plant managers, technical, production or maintenance managers – the seminar used technical presentations and interactive workshops to provide practical answers on lowering energy costs, increasing production quality, current product and market developments as well as analysis and optimization opportunitiesGrinding Seminar Christian Pfeiffer“The seminar is designed for operation, process and production personnel” Aims of the seminar Heat efficiency, plant availability, reduced emissions, alternative fuel suitability, and reduced maintenance costs are critical factors in the cement process technology, enabling the cement industry to cope with the challenges it is facing todayCEMENT PROCESS TECHNOLOGY SEMINAR The Cement Institute

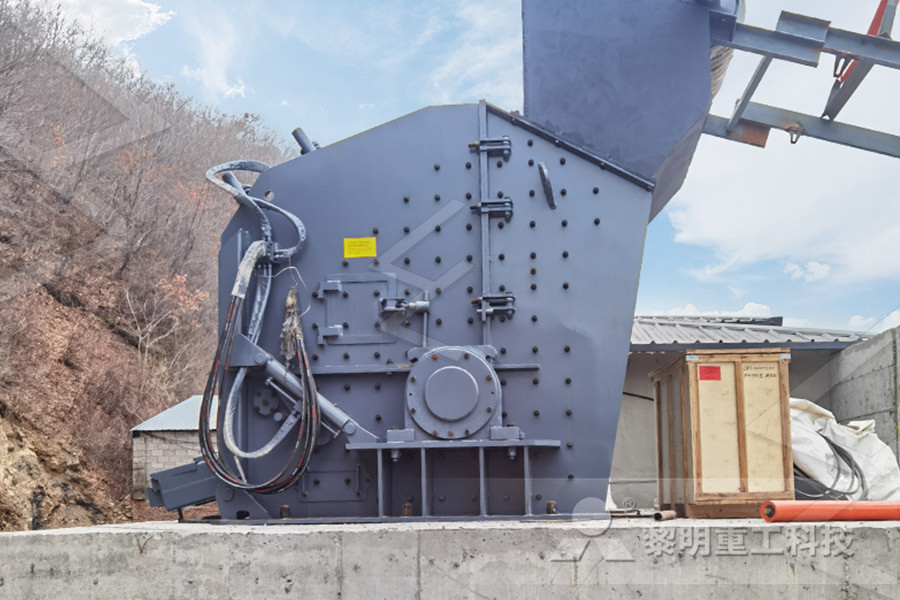

AMIT 129: Lesson 12 Crusher and Mill Operation Safety

Crusher and Mill Maintenance Hazards during maintenance are many including falls, being caught in moving equipment and being crushed by heavy components Recently an overseas operator with more than 4 years experience was killed when a heavy jaw crusher liner Ball mill Wikipedia A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing , The general idea behind the ball mill is an ancient one, but it was not until the industrial revolution and the , and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramicsone point lesson of cement mill ball millTCI online training courses where you learn practical solutions with a worldclass methodology for the cement industry Designed to provide a complete learning experience with innovative, dynamic, and interactive classes through multimedia tools, student collaboration opportunities, and formative assessment and feedbackOnline Training The Cement Institute

ballmill operation and maintainance

Oct 17, 2016 The Ball Mill operation and maintenance seminar will offer the participants the ability to be trained on the mill technology and components More Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance preventive and reactive to achieve energy savings reduced maintenance costs and overall improved productivity of the ball mill systemstraining to ball mill motorsME068: Ball Mill Operations and Maintenance This ball mill training course is designed to train each participant on the overall technology, operation and maintenance of the ball mill cement grinding system The training course focuses on the latest best practices for the operation and maintenance of ball mill systems to allow for optimal cement production, energy savings, reduced maintenance ball mill maintenance course

Ball Mill Maintenance In Mine Plant

Operations and maintenance training for ball mills Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill How to do the Ball Mill Repair Operations and maintenance training for ball mills Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill Ball Mills Mineral Processing ball mill capacity tph maintenance and trouble shootingDec 05, 2014 This is the only way to ensure safe operation and long life span The operators should take certain precautions before they start operating a ball mill Here’s a list of the most important safety maintenance steps that all operators should follow when using a ball mill: Planning – Planning ahead is a must Operators should know exactly when Ball Mill Safety Maintenance Steps To Follow StepsTo

ball mill operation and maintenance pdf

Ball mills operations and maintenance seminar Learn how to optimise your ball mill systems in this 5day training seminar focused on best practices for operations and maintenance (preventive and reactive) to achieve energy savings, reduced maintenance costs and overall improved productivity of the ball mill systemsSep 11, 2015 Putting a Ball or SAG Mill on Care and Maintenance The mine is closed and now you need to know how to put the SAG or Large Ball Mill in care and maintenance does not have to be complicated to the point where you need bridge erection equipment for lifting a Mill (AG/SAG/Rod/Ball) You actually need to lift a car higher than a millPutting a Ball or SAG Mill on Care and MaintenanceInstallation, Operation, and Maintenance Manual 2 CamTite Ball Valve Installation, Operation, and Maintenance Manual Instruction and training can be carried out by either ITT or the reseller of the valve by order of the operating companyRoller Mill Maintenance CPM, aspects, maintenance and operation of the equipment is remarkably similar Roller mill maintenance can be broken down into three operation and maintenance manual ball mill

1day Technical Seminar News, Events Training

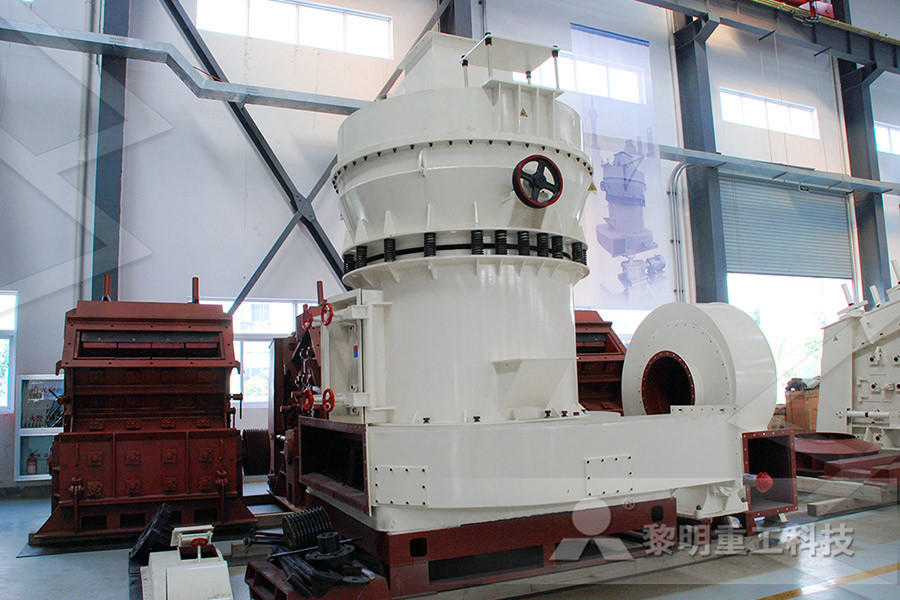

Ball Mill with Roller Press for pregrinding Feed Fines Feed Fines o Gained popularity in the 80’s to increase output by up to 30% in open pregrinding, or 50% in hybrid mode; o Plant is more complex and sensitive to feed variability / foreign matters, hence reliability / Crusher and Mill Maintenance Hazards during maintenance are many including falls, being caught in moving equipment and being crushed by heavy components Recently an overseas operator with more than 4 years experience was killed when a heavy jaw crusher liner AMIT 129: Lesson 12 Crusher and Mill Operation Safety Ball mill inspection 2 Inspection during operation Key benefits uses its many years of experience and the knowledge gained Bearing lubrication system Trunnion Root cause analysis from installing almost 4000 ball mills Mill shell around the world to carry out essential Mill head bolts Performed during both normal ball mill inspections(PDF) Ball mill inspection Andrea Jimenez Academiaedu

Ball Mill SlideShare

Nov 18, 2008 Basic principle Ball mill is generally used to grind material 1/4 inch and finer, down to the particle size of 20 to 75 microns To achieve a reasonable efficiency with ball mills, they must be operated in a closed system There is a specific operating speed for most efficient grindingNov 01, 2021 During full operations, the mill operates with a huge crusher, three ball mills, banks of flotation tanks and drying filters 24 hours a day, except for the crusher And up to 200 workers live in a Alexco working to remediate image at mine site near Keno