BENEFICIATION OF IRON ORE nitrklac

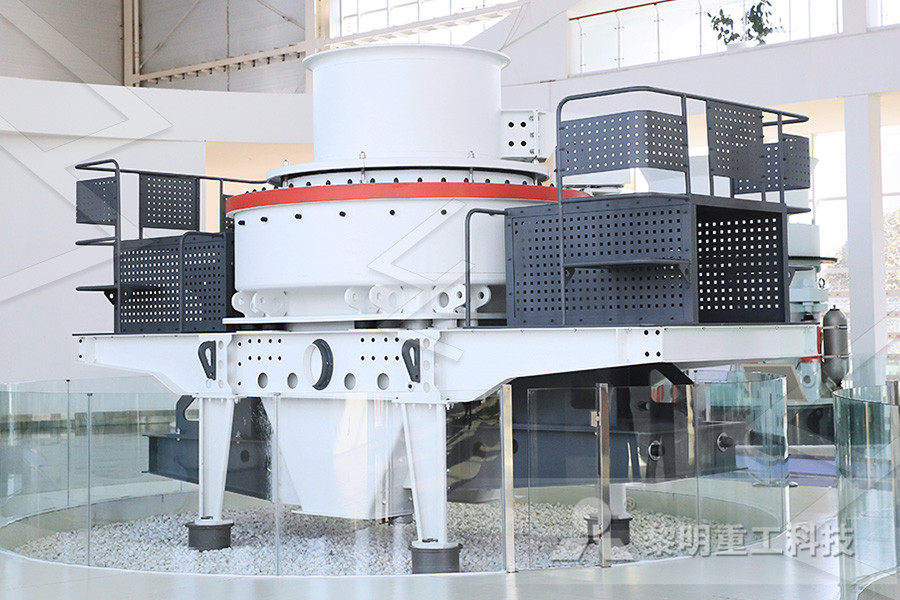

silica in iron ore leading to slime generation which are disposed of in tailing ponds Slime in these tailing ponds contains iron values in the range of 4560% Appropriate beneficiation process has to be advanced to reduce the waste generation in mines and for beneficiation iron ore crusher process 02/04/2021 crushed iron ore beneficiation process Iron ore beneficiation plant flow: The iron ore is preliminarily crushed by jaw crusher,after crushing to a reasonable size through lifting machine, feeder evenly into the ball mill for crushing, grinding After the grinding of ball mill the fine ore material is expected to enter the next process beneficiation of iron ore crusher process flowApr 27, 2017 Iron Ore Beneficiation Process During the last ten years great strides have been made, on the Mesabi range, in the practice of beneficiating low grade iron ore material By beneficiation is meant all methods of removing impurities, and raising the iron content to a point where it can be sold in open market, the principal impurities being Iron Ore Beneficiation Process

Iron Ore Beneficiation Multotec

Iron Ore beneficiation solutions from Multotec are designed so that each stage of the mineral beneficiation process, from ROM stockpiles to processed minerals and tailings, reduce overheads and lower your overall cost per ton Multotec’s beneficiation equipment provides peace of mind with supply, installation and asset management and flow sheet solutions all managed by experts in their fieldsWe use cookies to improve your experience on our website By using our site you agree to Cookies PolicyIron Ore Processing Flowsheet MultotecApr 03, 2014 Fig 1 A typical flow sheet of iron ore beneficiation plant Some of the common methods/techniques applicable for iron ore processing are described below Crushing, grinding and screening technique The purpose of grinding and regrinding is to reduce the ore to a size small enough to liberate and recover the valuable mineralsBeneficiation of Iron Ores – IspatGuru

Beneficiation of Iron Ores PHDessay

Mar 27, 2018 A typical flow sheet for iron ore benefaction plant is shown in Fig 1 3/13 Fig 1 A typical flow sheet of iron ore benefaction plant Some of the common methods/ techniques applicable for iron ore processing are described below Order custom essay Beneficiation of Iron Ores with free plagiarism The process is used for iron ore fines with Critical Issues With Water Iron Ore Beneficiation Plants > Water is critical for ore processing and in short supply > Three magnetite projects 3 different solutions Process Flowsheet > HPGR to 3mm > Coarse cobbing > Primary grind P80 55 µm > Intermediate magneticCritical Issues With Water Iron Ore Beneficiation PlantsA direct reduction (DR) grade pellet feed concentrate assaying 67 per cent Fe with a yield of about 28 31 per cent and iron recovery about 53 57 per cent could also be produced Based on the test work, a process flow sheet was developed to beneficiate the BHQ ore for production of Development of a Process Flow Sheet for Beneficiation of

Ore Beneficiation an overview ScienceDirect Topics

Microbially induced iron ore formation has been confirmed at Gunma iron ore mine, Japan [21] Ubiquitous microorganisms inhabiting iron ore deposits are useful in iron ore beneficiation (eg, removal of alkalis, silica, clays, phosphorous, and alumina) Because the presence of phosphorous in the iron ore promotes bacterial growth (as an energy Feb 01, 2018 Lowgrade iron ore received from the West Singhbhum area of Jharkhand state in India was used to develop a beneficiation flow sheet to remove alumina (Al 2 O 3) and silica (SiO 2) from the ore to get iron (Fe)rich product for steel plantsMineral characterization showed that the main mineral constituents present in the head sample are goethite, limonite, hematite, quartz, clay and gibbsiteDevelopment of process for beneficiation of lowgrade iron Oct 29, 2012 Iron Ore Beneficiation Process Flow Chart For Processing Plant Iron Ore Beneficiation Process Flow Chart 593 Views Iron Ore Beneficiation Process Iron ore beneficiation process includes feeder, crusher, ball mill, classifier » More detailedflow chart for iron ore beneficiation Mining

A simple framework for developing a concept beneficiation

A simple framework for developing a concept beneficiation flow sheet The Journal of The Southern African Institute of Mining and Metallurgy VOLUME 114 JULY 2014 549 Figure 2 – Xray diffraction patterns for two different forms of TiO2 (University of Arizona, nd) Figure 3—An iron ore sample containing three different ironbearingBeneficiation Plant Flow Sheet flow sheet design for iron ore benifiion plant flowsheet design and development for coal beneficiation plant 35MTPA Fine Iron Ore >>GET MORE Gold Beneficiation Machine,Gold mining process plantGold Beneficiation Plants FlowsheetIndustrial Mineral Processing Plant We are one of the leading manufacturer and exporter of Mineral Ore Beneficiation Plant Machines, fabricated from superior quality of raw materialsThese plants machines, specially designed for highest pressure performance, and are used in an assortment of applicationsSome of the features of these plants and machines are precision functionality, optimum Industrial Mineral Processing Plant Iron Ore

Slide 1

Once the iron ore has been mined and processed, it is melted in a blast furnace into pig iron This is then cast and rolled into semiproducts such as beams, bars, tubes and sheets, which can be used to manufacture enduse products, eg cars and buildings Fabrication scrap and endoflife scrap are also used in steel manufacturing1 a process for pruducing a high purity molbdenum product which comprises the steps of extracting a molybdenite ore produce a particulated cencentrate having an average particle size of less than about 200 mesh and consisting predominantly of mos2, oxidizing said concentrate to convert substantially all the mos2 to molybdenum oxide, contacting the oxidized said concentrate with an aqueous USA Process for producing high purity molybdenum Life cycle greenhouse gas emissions and other impacts from recycling activities: a case study in Thailand Nirmala Menikpura Institute of Global Environmental Strategies (IGES) * Gigesorjp

Driving value Understanding the potential

Dec 12, 2013 Los Bronces grades/El Soldado fault impacting production Copper Plan ~5060kt lower production Los Bronces and El Soldado stripping and process debottlenecking Collahuasi stripping to access higher grade ore / increased throughput ~150kt higher production Sishen mining rates constrained by inadequate waste stripping Iron ore Plan ~3035Mt In this process, a falling stream of iron ore concentrate is directly converted to metallic iron by reducing gases such as hydrogen, natural gas, or coal gas in a flash process This novel flash ironmaking technology (FIT) aims at overcoming the shortcomings of the conventional blast furnace (BF) technology101007@978 3 030 36540 0 PDF Metallurgy SteelmakingA simplified flowsheet typical of the flotation beneficiation process (with KCl floated) is presented in Figure 26 (14,22) Typically, the coarselycrushed slyvinite ore is sent to a grinding circuit where it is crushed and screened to give a 6 mesh fraction Grinding to 6 mesh frees the individual KCl and NaCl particles in the oreInorganic Fertilizer And Phosphate Mining Industries

Form 40F/A SECgov

EXPLANATORY NOTE In accordance with General Instruction B(1) of Form 40F, Quest Rare Minerals Ltd (the “Corporation” or “Registrant”) hereby incorporates by reference Exhibits 993, 999 to 9911, 9913 and 9914 as set forth in the Exhibit Index attached to this Amendment No 1 to the Annual Report on Form 40F The Corporation prepared and filed an amended and restated annual May 24, 2016 May 24, 2016 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are Beneficiation of Iron Ore Mineral Processing MetallurgyApr 27, 2017 Apr 27, 2017 Iron Ore Beneficiation Process During the last ten years great strides have been made, on the Mesabi range, in the practice of beneficiating low grade iron ore material By beneficiation is meant all methods of removing Iron Ore Beneficiation Process

Iron Ore Processing Flowsheet Multotec

We use cookies to improve your experience on our website By using our site you agree to Cookies PolicyIron Ore beneficiation solutions from Multotec are designed so that each stage of the mineral beneficiation process, from ROM stockpiles to processed minerals and tailings, reduce overheads and lower your overall cost per ton Multotec’s beneficiation equipment provides peace of mind with supply, installation and asset management and flow sheet solutions all managed by experts in their fieldsIron Ore Beneficiation Multotecsilica in iron ore leading to slime generation which are disposed of in tailing ponds Slime in these tailing ponds contains iron values in the range of 4560% Appropriate beneficiation process has to be advanced to reduce the waste generation in mines and for BENEFICIATION OF IRON ORE nitrklac

Beneficiation of Iron Ores – IspatGuru

Apr 03, 2014 Apr 03, 2014 Fig 1 A typical flow sheet of iron ore beneficiation plant Some of the common methods/techniques applicable for iron ore processing are described below Crushing, grinding and screening technique The purpose of grinding and regrinding is to reduce the ore to a size small enough to liberate and recover the valuable mineralsA simple framework for developing a concept beneficiation flow sheet The Journal of The Southern African Institute of Mining and Metallurgy VOLUME 114 JULY 2014 549 Figure 2 – Xray diffraction patterns for two different forms of TiO2 (University of Arizona, nd) Figure 3—An iron ore sample containing three different ironbearingA simple framework for developing a concept beneficiation iron ore is expected to rise by more than 200 million tonne per year to meet the internal demand export This additional requirement of iron ore will need beneficiation of low grade ore/fines to get the major portion of increased demand This paper deals in brief to use of available methodologies for beneficiation of iron ore in Indian contextAdvances in Low Grade Iron Ore Beneficiation

UTILIZATION OF IRON ORE SLIME IN INDIA AN REVIEW DR

Diagram 2 Complete flow sheet for beneficiation of Chitradurga iron ore slime[8] The above process sheet describes that beneficiation process carried out in Chitradurga iron ore slime beneficiation plant ,the slime was collected and size analysis were done, the sizeThe process flow chart of Coal Gasifier is given in figure below Process Flow Diagram for Coal Gasifier Upgragation of Existing Iron Ore Grinding Unit to 10 MTPA Iron Ore Grinding and Beneficiation Unit The Iron ore fines which are being fed to the existing 06 MTPA Pellet Plant is being grinded through an Iron Ore Grinding UnitEXECUTIVE SUMMARYThe first step of physical beneficiation is crushing and grinding the iron ore to its liberation size, the maximum size where individual particles of gangue are separated from the iron minerals A flow sheet of a typical iron ore crushing and grinding circuit is shown in Figure 122 (based on Ref [4])This type of flow sheet is usually followed when the crude ore contains below 30% ironPhysical Beneficiation an overview ScienceDirect Topics

Iron Ore Processing Flowsheet Grinder Process

The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet Processing The primary beneficiation plant consists of only a jaw crusher and from there the material is transferred to the secondary plant via conveyor belt method The main objective of the primary beneficiation plant is the crushing of the ROM from the Processing Iron Ore157 Мб PROCESSING TECHNOLOGIES I For beneficiation of iron ore, Tenova3 FEED PREPARATION PLANTS RunofMine (ROM) ore is prepared for processing by removing unwantedI Scrubbers Scrubbers are used to process ores with clay contents that pose a problem further in the process flowProcess Flow Diagram Of Iron Ore Beneficiation PlantExperimental study on the beneficiation of lowgrade iron ore fines using hydrocyclone desliming, reduction roasting and magnetic separation Beneficiation of 2 mm lowgrade iron ore tailings (507% Fe, 108% SiO2 and 44% Al2O3) from Western Australia was studiedIron Ore Beneficiation Research Papers Academiaedu