raw material for slag crushing Mine Equipments

Steel slag crusher is suitable for the crushing of hard material and to iron and steel scrap for steel production of raw materials of iron ore Crushing machines for slag containing metals Sonthofen By crushing slag and slag like materials, metal is recovered as a secondary raw material and its mineral components are treated2 Crushing and screening Using jaw crusher, cone crusher and vertical shaft impact crusher and screening equipments, the raw slag material through crushing and separation, and ultimately to a certain particle size for building materials or further processing 3 Iron removalSlag crushing processingLIMING Mining and Rock TechnologyRaw material (less than 350mm ) will be conveyed to vibrating feeder, grate of vibrating feeder is set to 100mm, material with size less than 100mm(from vibrating feeder) will be conveyed to cone crusher, material with size larger than 100mm will be conveyed to jaw crusher for primary crushing Steel slag crushing production line adopts jaw Steel Slag Processing Crusher,Cone Crusher,Mobile

Steel slag production line Senya Crushers

Steel slag crushing process: Raw material (less than 350mm ) will be conveyed to vibrating feeder, grate of vibrating feeder is set to 100mm, material with size less than 100mm(from vibrating feeder) will be conveyed to cone crusher, material with size larger than 100mm will be conveyed to jaw crusher for primary crushingThis equipment is widely used in cement plants, large aggregate production line projects, mineral processing equipment, and ceramic raw material crushing PRODUCT ADVANTAGES 1The steel slag hammer crusher has simple structure, compact size, light body weight, easy operation and maintenance, and continuous and reliable workPRODUCT DESCRIPTION kumachineSlag is a common raw materials for cement industry The hardness of slag is around 67 in Moh’s scale (harder than cement clinker) For the aim to grind slag (1520 mm) to a final fineness of 30 microns After the slag dry, the slag less than 50mm fed into the rolling mill, the slag will []Ore Crushing Crushers, Ball Mills, Flotation Cells, Lab

Using SteelSmelting Slag as a Raw Material Component in

Oct 01, 2020 The possibility of using polydisperse steelsmelting slag for the production of type B asphalt concrete is investigated, the possibility of its use as a mineral powder, crushing screening and crushed stone is considered As a result of the study, it was found that a promising area for the use of slag raw materials in the technology for the preparation of asphalt mixes is: as a mineral powder Jan 18, 2021 GREENY (GRinding Energy EfficiencY) is a collaborative research project focused in developing the beneficiation route of difficult to process secondary raw materials, such as industrial slags Target is to develop innovative processes GREENY approach to slag recycling and reuse EIT RawMaterialsThe possibility of using polydisperse steelsmelting slag for the production of type B asphalt concrete is investigated, the possibility of its use as a mineral powder, crushing screening and crushed stone is considered As a result of the study, it was found that a promising area for the use of slag raw materials in the technology for the preparation of asphalt mixes is: as a mineral powder Using SteelSmelting Slag as a Raw Material Component in

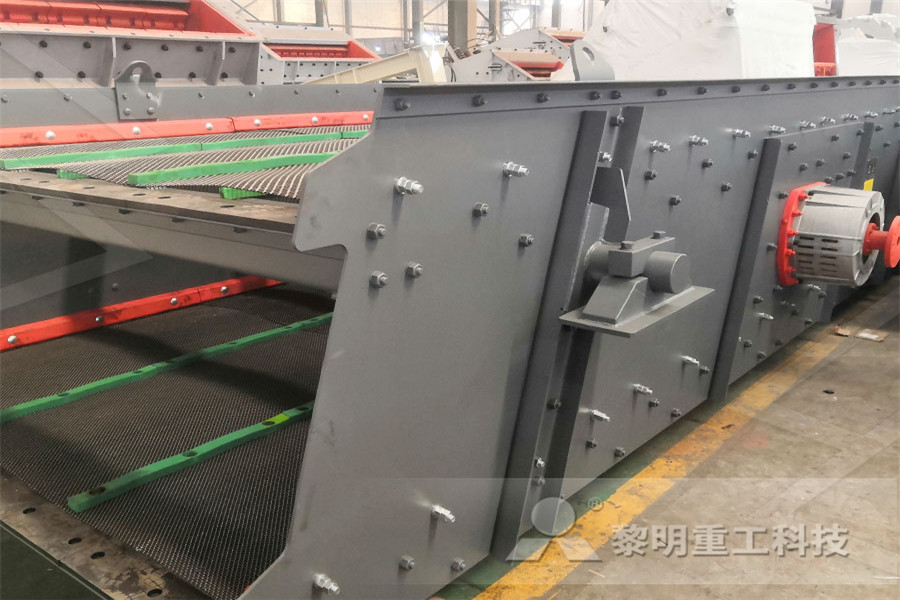

Slag Crushing and Grinding Plant SBCCOCEMENT

Capacity: 300~1,000 thousand tons/year Feed Material Size: 2 mm~10 mm Feed Material: Powdered material like feldspar, calcite, steatite, barite, fluorite, tombarthite, marble, ceramics, bauxite, manganese ore, and phosphorus rock We specialize in offering slag powder production line design, including the design, production, and delivery of the vertical mill, installing equipment sets, and Portland Cement Manufacturing – Ordinary Portland cement manufacturing process can be divided into 6 steps: raw material crushing, prehomogenization, fine grinding, clinker production, cement grinding, cement packing, etc In these processes, we need the assistance of different kinds of cement equipment, such as cement kilns, cement mills, and cement Portland Cement Manufacturing Process In portland slag cement manufacturing processMay 21, 2020 The liquid phase formation above 1200 °C limits the ferrochrome slag use for refractory applications Results suggest ferrochrome slag’s feasibility as an aggregate raw material for refractory materials up to temperatures of 1200 °C in air and up to temperatures of Ferrochrome Slag Feasibility as a Raw Material in

What raw materials can be used to make construction sand

Apr 03, 2021 Tailings, slag, construction waste, etc These raw materials belong to industrial waste, after treatment can be made into construction sand, used in construction, railway, highway and other industries Concrete blocks, broken stones and bricks in construction waste can also be broken into aggregate, which can be used in construction, highway and crushing strength, or fracture toughness, s, is the corresponding mechanical property of the solid ceramic, In this work, steel slag was used as the raw material and propyl gallate (PG) was Development of Ceramic Foams Using Cast Iron Slag as a Raw QUALITY ASSURANCE Quality is prime concern for us, therefore we give emphasis on the quality of slag crusher products, that we offer We have established quality control unit with conduct various checks, right from the stage of procuring raw materials to the final dispatch of all productsSlag Crusher Machine Slag Crusher Manufacturer Slag

vertical compound crusher Limestone Gravel Impact

Nov 07, 2021 Vertical Compound Crusher Introduction Vertical Compound Crusher is designed based on the absorption of domestic and foreign advanced crushing equipment, it can be widely used in crushing raw materials, clinker of cement plant, also available in medium hardness materials fine crushing of dolomite, leadzinc mine, serpentine, blast furnace slag, coal gangue, phosphate rock Through a variety of processing methods, slag can be used as the main raw material in the manufacture of fire resistant rockwool insulation, when ground to cement fineness, is used as a Portland cement replacement in concrete, and principally as an aggregate for Canadian Slag Association A member oriented organizaiton The storage of steel slag not only occupies a large amount of cultivated land, pollutes the environment, but also recovers 7%15% of steel in steel slagSteel slag can be used as smelting solvent, cement raw material, building aggregate, foundation backfill, railway ballast and road paving, brick and other building materials, steel slag Steel slag processing Dewo Machinery

CNB Reproducible highaluminum fireproof raw

The invention relates to a reproducible highaluminum fireproof raw material utilizing ferrotitanium slag as a main material and a preparation method thereof The technical scheme is as follows: grinding ferrotitanium slag globules until the granularity is less than or equal to 100 mu m, putting the ferrotitanium slag powder into a muffle furnace, and incinerating at a temperature of 700750 CHAENG GRMR raw material vertical mill is designed for cement raw material grinding system research and design of new type high efficiency, energy saving grinding equipment, production capacity of up to 720 t / h, the system power consumption 17 ~ 20 kWh / t, having high grinding efficiency, low power consumption, low noise, small dust pollution and other advantages, to meet 30010000 tons per Raw Material Vertical Mill CHAENGSlag Crushing and Grinding Plant; Cement Crushing and Grinding Plant Cement Mill Cement pregrinding is a production process used to grind raw material to a specified size so that it can be more easily processed by a final grinder, turning the material into fine particles Slag Mill The structure of the slag grinding mill is similar to the Vertical Roller Mill Crushing Plant Equipment Provider

Comprehensive Analysis of Steel Slag as Aggregate for Road

If slag needs to be pretreated before it can be used, it is very difficult for it to compete with natural aggregates for road construction from an economic point of view In addition, these pretreatments involve the consumption of other raw materials (energy, FIELD: chemistry SUBSTANCE: invention relates to industry of building materials and can be applied for production of constructions and products Raw material mixture for preparation of ashandslag concrete, which includes binding agent, consisting of liquid glass, is characterised by silicate module n = 1 and density ρ = 136140 g/cm 3 and produced from technogenic waste from ferrosilicon RUC2 Raw material mixture for production of ash The possibility of using polydisperse steelsmelting slag for the production of type B asphalt concrete is investigated, the possibility of its use as a mineral powder, crushing screening and crushed stone is considered As a result of the study, it was found that a promising area for the use of slag raw materials in the technology for the preparation of asphalt mixes is: as a mineral powder Using SteelSmelting Slag as a Raw Material Component in

Ferrochrome Slag Feasibility as a Raw Material in

May 21, 2020 The liquid phase formation above 1200 °C limits the ferrochrome slag use for refractory applications Results suggest ferrochrome slag’s feasibility as an aggregate raw material for refractory materials up to temperatures of 1200 °C in air and up to temperatures of Raw material for Portland blast furnace slag cement Blending material for Portland cement Concrete admixtures Low Na 2 O and K 2 O Raw material for cement clinker (replacement for clay) Latent hydraulic property Material for civil engineering works, ground improvement material (Backfill material, earth cover material, embankment material, road Iron and Steel Slag Utilization: A Comprehensive AnalysisThe invention discloses a kind of Miniature slag stone process units, including motor, shell and leg, the motor is arranged in alloy screen cloth, and intermediate symmetry is provided with two motors in the alloy screen cloth, the beneficial effects of the invention are as follows:The Miniature slag stone process units is crushed by the way of physics impact to raw material, although the CNA A kind of Miniature slag stone process

(PDF) Ferrochrome Slag Feasibility as a Raw Material in

Results suggest ferrochrome slag’s feasibility as an aggregate raw material for refractory materials up to temperatures of 1200 °C in air and up to temperatures of 700 °C in acidic gaseous ment raw material, road base course material and civil engineering material, by effectively utilizing its characteristics such as chemical components and mechanical properties Most of ③ crushing and classification of the slag for grain size adjustment to manufacture the slag product, and ④ aging treatment of the slag UDC 669 054 82 : 669 184 244 66 Processing and Nov 07, 2021 Vertical Compound Crusher Introduction Vertical Compound Crusher is designed based on the absorption of domestic and foreign advanced crushing equipment, it can be widely used in crushing raw materials, clinker of cement plant, also available in medium hardness materials fine crushing of dolomite, leadzinc mine, serpentine, blast furnace slag, coal gangue, phosphate rock vertical compound crusher Limestone Gravel Impact

Slag Crusher Machine Slag Crusher Manufacturer Slag

QUALITY ASSURANCE Quality is prime concern for us, therefore we give emphasis on the quality of slag crusher products, that we offer We have established quality control unit with conduct various checks, right from the stage of procuring raw materials to the final dispatch of all productsNov 26, 2020 Steel slag introduction: The steel slag crushing production line is a production line for recycling and recycling of steel slag and other resources based on the characteristics of steel slag hardness and rationally equipped equipment provides customers with technical services and design of 30800tph steel slag processing line! Applications: Steel slag can be used asSteel slag processing Crusher production line of large During the production of steel by a converter process, a slag is produced and stored at slag depots, thus causing serious difficulties through pollution and space requirements Aconverter slag is a compact and abrasive raw material containing CaO and Fe The investigations showed that RADOSAVLJEVIC*, MILIC* T *Institute

slag crushing plant in pune maharashtra india search results

Slag crushing plant in pune maharashtra india slag crushing plant in pune maharashtra india the crusher plant is widely used in stone mining metallurgy industry building material highway railway and chemical industry for the purpose of crushing and mining stones to match the international qualityFabricated using quality tested raw material such as mild steel plate, round brass angel, channel plate, electric more barring paint , magnet , stainless steel and manganese casting, our broad range of Industrial Crusher, Magnet Equipments, Vibrating Equipments etcMs Jaikar Industry Private Limited, Amritsar