clay dryer, kaolin cly dryer,bentonite clay dryer

Clay Rotary Dryer Introduction Dongding is a professional Rotary Drum Dryer manufacturer, we have more than 15year rotary dryer manufacturing with mature tech design Dongding Clay Rotary Dryer is manufactured to dry kinds of soil clay, includes ,bentonite clay, Partition plates increase the heating surface Drying may be by hot air or exhaust gases from other operations If this drying gas has a deleterious effect on the Rotary Dryer Design Working Principle The rotary dryer also known as drum dryer is a kind of industrial dryer that can dry high humidity moisture materials by direct or indirect heating, Its body is a tilted or horizontal and rotating cylinder, Rotary drum dryer occupies a very important position in the chemical, agricultural, coal, building materials, and light industrial industriesRotary Dryer Working Principle, Design,Drying System , Uses

(PDF) Development of Software for Design and

Development of Software for Design and Construction of Rotary Dryer for Drying Ground Cassava September 2016 International Journal of Engineering and Technology Rotary dryers for particulate solids commonly use flights along the length of the shell to lift solids and make them rain across the dryer section These flights are critical to dryer performance Previous models for the prediction of the solids holdup in rotary drums have assumed that the angle of the solids level in a flight is independent of The design of flights in rotary dryers ScienceDirect the process, the clay has a moisture content of 10 to 15 percent For certain applications, the clay is dried in mechanical dryers to reduce the moisture content of the material to 7 percent or less Typically, rotary and vibrating grate dryers fired with natural gas or fuel oil are used for drying fire clay1125 Clay Processing US EPA

CALCINED CLAYS Clay calcining technologies: the rotary

the short rotary cooler Due to the high lengthtodiameter ratio and the low feedstock moisture, no lifters were considered The kiln will have a 450tpd capacity for clay calcination, with a heat consumption of 720kcal/kg Calcined clay capacity then becomes 35 per cent higher than that of its design clinker production capacity The main machinery comprises a rotary dryer, rotary kiln and cooler In the meanwhile, the original design of the clay calcination line has been replaced and revamped due to inefficiencies and deficiencies CGH ordered from thyssenkrupp Latest trends in clay activation Cement Lime Gypsum(c) The owner or operator of a ball clay rotary dryer, a diatomite rotary dryer, a feldspar fluid bed dryer, a fuller's earth rotary dryer, a gypsum rotary dryer, a gypsum flash calciner, gypsum kettle calciner, an industrial sand rotary dryer, a kaolin rotary dryer, a kaolin multiple hearth furnace, a perlite expansion furnace, a talc flash eCFR :: 40 CFR Part 60 Subpart UUU Standards of

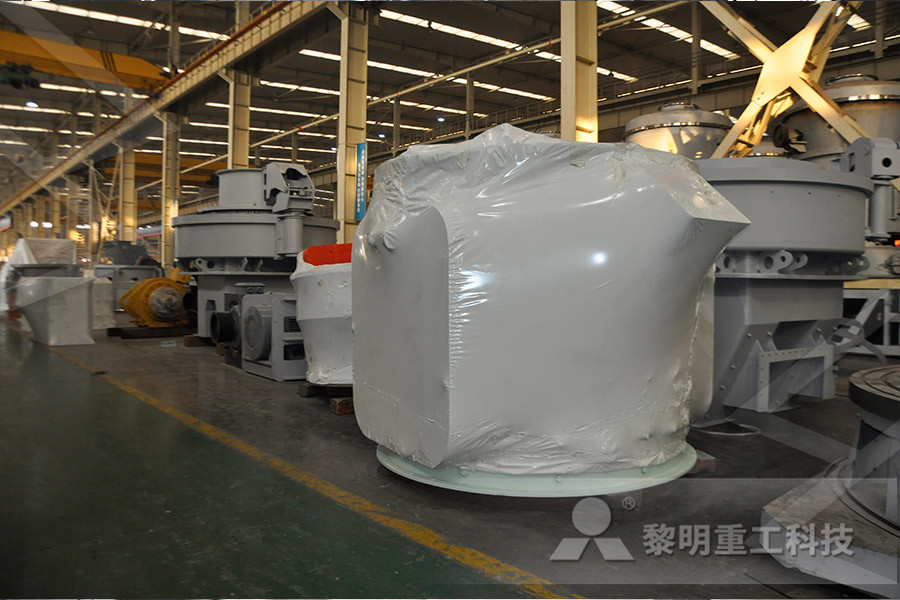

China New Design Rotary Sand Dryer Used for Drying Clay

China New Design Rotary Sand Dryer Used for Drying Clay, Fly Ash, Pozzolan, Find details about China Coal Ash Dryer, Fly Ash Dryer from New Design Rotary Sand Dryer Used for Drying Clay, Fly Ash, Pozzolan Zhengzhou Jiutian Technology Machinery Co, Ltd Aimed at features of clay, Taeda adopts new rational design suitable for drying clay and similar materials With crushing and cleaning device, Taeda clay dryer can reduce moisture of clay materials to lower than 5% from 25% one time Whole system is featured in large capacity, low energy consumption and low running costClay Dryer – Zonelion Taeda Rotary Dryer ManufacturerWe design and build all clay dryers custom to our customers’ requirements The choice for the ideal drying system depends on your products and your drying process We use rotary air mixers or pressurized wall systems to ensure the right air circulation in your dryer Because you need an ideal air mixing system to accurately homogeneously dry Clay Dryer – Industrial Drying Systems Blaauw

Jiangsu Manufacturing Large Capacity Active Clay Rotary

Based on the structure of a traditional rotary dryer, steam tube rotary dryer/ calcinator is equipped with some steam heating tubes inside of the dryer The heating tubes run through the dryer with pattern of 1 to 5 concentric circle(s), supplying heat needed by drying process The Rotary Dryers are one of the widely used Dryer in process industry Especially in fertilizer and minerals industry for drying products such as coal, clay, gypsum, kaolin, limestone, mineral sand, potash, silica sand etc Rotary Dryers from SAKA provide controlled, uniform and efficient drying to help you achieve desired product qualityROTARY DRYER – Saka the short rotary cooler Due to the high lengthtodiameter ratio and the low feedstock moisture, no lifters were considered The kiln will have a 450tpd capacity for clay calcination, with a heat consumption of 720kcal/kg Calcined clay capacity then becomes 35 per cent higher than that of its design clinker production capacityCALCINED CLAYS Clay calcining technologies: the rotary

The design of flights in rotary dryers ScienceDirect

Rotary dryers for particulate solids commonly use flights along the length of the shell to lift solids and make them rain across the dryer section These flights are critical to dryer performance Previous models for the prediction of the solids holdup in rotary drums have assumed that the angle of the solids level in a flight is independent of Development of Software for Design and Construction of Rotary Dryer for Drying Ground Cassava September 2016 International Journal of Engineering and Technology 6(8):260270(PDF) Development of Software for Design and Material Processing Agglomeration Clay is frequently agglomerated to improve handling and performance across many applications Whether you need to create a micropelletized product, or you’d like to turn fines into pellets, FEECO can serve all of your clay agglomeration and pelletizing needs with our agglomeration drums, disc pelletizers, pin mixers, and pug mills, as well as our complete Clay Processing Equipment

Design Parameters Of Rotary Kiln essonnementdeuchfr

Complete rotary dryer design and calculation PALET Jan 29, 2020 Rotary Dryer Detailed Description: Rotary Dryer from Qingdao Palet Machinery can reduce the biomass material moisture content from 4055% to below 10% 15% Read More The effects of rotary kiln operating conditions and designChina New Design Rotary Sand Dryer Used for Drying Clay, Fly Ash, Pozzolan, Find details about China Coal Ash Dryer, Fly Ash Dryer from New Design Rotary Sand Dryer Used for Drying Clay, Fly Ash, Pozzolan Zhengzhou Jiutian Technology Machinery Co, LtdChina New Design Rotary Sand Dryer Used for Drying Clay Aimed at features of clay, Taeda adopts new rational design suitable for drying clay and similar materials With crushing and cleaning device, Taeda clay dryer can reduce moisture of clay materials to lower than 5% from 25% one time Whole system is featured in large capacity, low energy consumption and low running costClay Dryer – Zonelion Taeda Rotary Dryer Manufacturer

Clay Brick Making Brick Dryer (Rotary) Brick

Technologies Borna Gostar Company has been achieved new technologies to make rotary rapid dryer One of these technologies is the design and manufacture of the Vane Axial Fan with an efficiency of about 90% All Airfoils and static blades of this fan are engineered by company engineers without any reverse engineering, making it possible to provide highefficiency dryers Partition plates increase the heating surface Drying may be by hot air or exhaust gases from other operations If this drying gas has a deleterious effect on the product, then an indirect type of dryer can be supplied A further derivation is the Rotary Dryer Design Working PrincipleWe design and build all clay dryers custom to our customers’ requirements The choice for the ideal drying system depends on your products and your drying process We use rotary air mixers or pressurized wall systems to ensure the right air circulation in your dryer Because you need an ideal air mixing system to accurately homogeneously dry Clay Dryer – Industrial Drying Systems Blaauw

Drying Technologies for Mineral Raw Materials

For coarsegrained materials, clay products, broken glass, etc Doubleshell drum TT Tripleshell drum TTT For drying of finegrained minerals, silica sand and ore For drying materials which require long dwell times For easily freeflowing products with fine to medium grain sizes Allgaier rotary drum dryers are used, particularlyRotary dryers for particulate solids commonly use flights along the length of the shell to lift solids and make them rain across the dryer section These flights are critical to dryer performance Previous models for the prediction of the solids holdup in rotary drums have assumed that the angle of the solids level in a flight is independent of The design of flights in rotary dryers ScienceDirectRotary dryers consist of a rotating cylindrical shell that can be horizontal or slightly inclined In a rotary dryer the heat transfer mechanism can be either direct or indirect Directheat rotary dryers are more common than indirectheat rotary dryers Shown here is a rotary dryer getting installedDryers Visual Encyclopedia of Chemical Engineering

Dryers and Drying Process PDF

DRYERS AND DRYING PROCESS DRYERS • Is a mass transfer process consisting of the removal of water or another solvent by evaporation from a solid, semisolid or liquid • This process is often used as a final production step before selling or packaging products Methods of dryers Hot air (direct drying) • Air heating increases the drying force for heat transfer and accelerates drying appendix b1 particle size distribution data and sized emission factors for selected sources 10/86 (reformatted 1/95) appendix b1 b11AP 42, Appendix B1: Particle Size Distribution Data and