Jaw Plates The Right Jaw Plates for the Jaw Crushers and

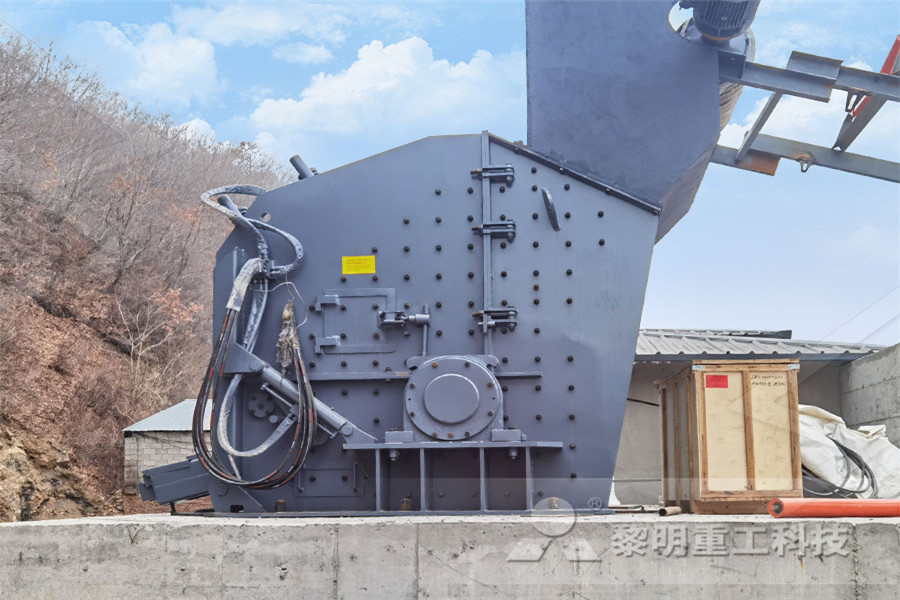

Nov 05, 2021 The jaw plates of a jaw crusher play an integral role in determining the type of material it can process Different materials require different types of crushing, and selecting the wrong plate for your machine could lead to high operating costs as well as costly repairs or downtimeSep 02, 2021 The jaw plate is an important part in the jaw crusher equipment, and its service life directly affects the whole jaw crusher equipmentTherefore, you must consider the hardness and toughness of the jaw plate when you want to choose a correct oneJaw Plates: How to Choose the Right One for Different May 09, 2021 The jaw plate is a most important component in the jaw crusher machine and also its life of solution is directly impacting the total jaw crusher equipment Hence, you ought to think about the sturdiness along with hardness of a jaw plate, when you really need to pick the ideal oneHow To Choose The Best Material For Jaw Crusher Plates

How to choose the best jaw plates for your jaw crusher

The jaw plate is really the most significant component in the jaw crusher equipment as its overall service life directly influences the whole jaw crusher equipment This is why it is crucial to find an appropriate jaw plate with sufficient solidity as well as sturdiness while looking on the marketMar 14, 2021 The jaw plate is in fact the most considerable part in the jaw crusher maker as its overall life span straight influences the entire jaw crusher machine This is why it is important to find a best jaw plate with adequate hardness as well as strength while searching on the marketJust how to select the ideal jaw plates for your jaw crusher?The jaw crusher plate is an exceptionally crucial element in your, and for that reason its service life straight affects the whole jaw crusher system When you need to select an appropriate one, you need to consider the hardness as well as toughness of this particular plateHow To Choose The Most Effective Jaw Crusher Plate For

How to choose the right product for jaw crusher plates?

Mar 15, 2021 The jaw plate is a most crucial component in the jaw crusher device and also its life of service is directly impacting the complete jaw crusher machine Hence, you ought to take into consideration the durability along with solidity of a jaw plate, Jul 16, 2021 These jaw crusher plates are often supplied to Indonesia when the firmness of this specific plate is specifically high, as then the thickness of the abrasive product pressed onto the jaw plate will certainly have a tendency to be considerably lower, which will certainly avoid the leading surface area from damagesExactly how To Select The Best Jaw Crusher Plate For Your Nov 26, 2020 The pivoted jaw swings around the pivot and makes an impact on the fixed jaw, crushing the fed lumps in the jaw crusher In order to decrease the replacement cost, choose the right material for your jaw crusher is the first thing BDI offers more jaw crusher plate styles than any manufacturer in the industry Each of these designs has been What happened? Jaw plates which need Crusher Wear Parts

The Most Practical Jaw Crusher Repair and Maintenance

Aug 28, 2021 There are different jaw plates material in the market, and some of them suits for hard stone while other is not Therefore, you have to choose the right jaw plate for your crusher For example, generally the jaw plate of single toggle jaw crusher is not good at crushing strongly abrasive and hard stone material with large productionLift the new jaw plate, and start the crane to hang the moving plate and the fixed plate separately Install the clamps, place the clamps in place, and tighten the screws Tighten the stationary plate screws and install the side plates Adjust the gap of the discharge port Start the jaw crusher and vibrate the mine for trial operationHow To Change Crusher Jaw Plate?Oct 02, 2020 Toggle plate is nothing but the most simple part of the Jaw Crusher, which is available in the market at a very low price and along with that it is designed in such a way that it is made by cast iron It is the driving part of the jaw crusher and along with that it includes the three functions that are mainHow to Change the Toggle Plate Jaw Crusher The Uplift

Jaw plate Quarrying Aggregates

Tag: Jaw plate How Long Can the Jaws of the Jaw Crusher be Used Parts The movable and fixed jaws of the jaw crusher are in direct contact with the materials and are used to squeeze all kinds of hard materials It is the most important wear part of the jaw crusher So how long can a set of jaws be used?Maximum distance between jaw plates for a given setting (this is the distance when the jaw is at rest) CLOSE SIDE SETTING Minimum distance between jaw plates derived from the OSS and the stroke DRIVE SIDE Side of the crusher fitted with a grooved pulley couple to the crusher drive NON DRIVE SIDE Opposite side of the crusher form the drive sideR Crusher Wear Parts Reference GuideUnicast jaw crusher wear parts are cast using M2, M19, or M22—work hardening alloys for optimum performance Titanium Carbide (TiC) options are available for even longer wear life Custom designed to suit your needs, Unicast Jaw Plates and Cheek Plates are engineered to suit the specific needs of your application Features BenefitsJaw Crusher Wear Parts Replacement jaw plates, cheek

Jaw Crusher Plate > Crusher Parts > Products >

We know that the jaw crusher spare parts maily include the fixed jaw plate and the movable jaw plate's Jaw crusher plates are manufactured with super high manganese steel, therefore they have a service life 50~100% longer than those made of traditional high manganese steel Every model of PE series jaw crushers in is tested for The jaw crusher is a machine for crushing rocks and other hard and abrasive materials, such as granite, ores or recycled concrete, usually for industrial purposes The crushing device consists of a fixed plate and a swing plate called jaws between which the rock is trapped and crushedChoosing the right crusher Buying Guides DirectIndustryAnswer: First of all NOT Chinese made, Then choose closed side minimum maximum product settings Then check thruput to ensure the TPH (tons per hour) are compatible with the rest of the crushing plant, ie: secondary crusher feed opening, discharge size Crushing reduction ratio should alwaysMining Industry: What a good way to choose a jaw crusher

Jaw Plates The Right Jaw Plates for the Jaw Crushers and

Nov 05, 2021 The jaw plates of a jaw crusher play an integral role in determining the type of material it can process Different materials require different types of crushing, and selecting the wrong plate for your machine could lead to high operating costs as well as costly repairs or downtimeSep 02, 2021 The jaw plate is an important part in the jaw crusher equipment, and its service life directly affects the whole jaw crusher equipmentTherefore, you must consider the hardness and toughness of the jaw plate when you want to choose a correct oneJaw Plates: How to Choose the Right One for Different Mar 14, 2021 The jaw plate is in fact the most considerable part in the jaw crusher maker as its overall life span straight influences the entire jaw crusher machine This is why it is important to find a best jaw plate with adequate hardness as well as strength while searching on the marketJust how to select the ideal jaw plates for your jaw crusher?

How To Choose The Most Effective Jaw Crusher Plate For

The jaw crusher plate is an exceptionally crucial element in your, and for that reason its service life straight affects the whole jaw crusher system When you need to select an appropriate one, you need to consider the hardness as well as toughness of this particular plateThe jaw plate is really the most significant component in the jaw crusher equipment as its overall service life directly influences the whole jaw crusher equipment This is why it is crucial to find an appropriate jaw plate with sufficient solidity as well as sturdiness while looking on the marketHow to choose the best jaw plates for your jaw crusher May 09, 2021 The jaw plate is a most important component in the jaw crusher machine and also its life of solution is directly impacting the total jaw crusher equipment Hence, you ought to think about the sturdiness along with hardness of a jaw plate, when you really need to pick the ideal oneHow To Choose The Best Material For Jaw Crusher Plates

How to pick the best product for jaw crusher plates?

The jaw plate is a most crucial element in the jaw crusher device as well as its life of solution is straight affecting the complete jaw crusher machine Hence, you must take into consideration the strength in addition to solidity of a jaw plate, when you truly require to choose the best oneMar 15, 2021 The jaw plate is a most crucial component in the jaw crusher device and also its life of service is directly impacting the complete jaw crusher machine Hence, you ought to take into consideration the durability along with solidity of a jaw plate, How to choose the right product for jaw crusher plates?Jul 16, 2021 These jaw crusher plates are often supplied to Indonesia when the firmness of this specific plate is specifically high, as then the thickness of the abrasive product pressed onto the jaw plate will certainly have a tendency to be considerably lower, which will certainly avoid the leading surface area from damagesExactly how To Select The Best Jaw Crusher Plate For Your

Jaw Crusher Liner Plate Design Profile Shapes

Jul 22, 2015 Jul 22, 2015 Jaw Crusher Liner Plate Design Profile Shapes Straight Jaw Plates: A shows a diagram of a standard type of Blake crusher with regular or straight jaw plates This type of plate has been the standard from the time of its inception, emulating, in this respect, the straight concaves in the gyratory machineHOW to Change JAW cruSher jaw plate👍👍👍HoW To Change JAW cruSher jaw plate YouTubeOct 17, 2017 Oct 17, 2017 For the jaw crusher with a complete connecting rod, the disassembly sequences of removing the thrust plate for jaw crusher equipment are as following: A The baffle bolts must be screwed off first, and then dry oil lubricating oil pipe can be cut off Hang the thrust plate of the jaw crusher equipment on the crane lifting hook or other lifting How to Replace the Thrust Plate of Jaw Crusher?