Cone Crusher VS Gyratory Crusher JXSC Mine

The cone crusher has 25 times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quickly Therefore, it is advantageous to the ore crushing, the crushing efficiency is high 2 Different applications In large quarries, gyratory crushers are often used as primary crushersJan 01, 2016 Primary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs Basically, gyratory crushers consist of a fixed solid conical shell or bowl (also called concaves) and a solid cone within the bowl called a breaking head (Figure 51)The breaking head is fixed to a central spindle, which is hydraulically suspended or Gyratory and Cone Crusher ScienceDirectJul 25, 2015 Difference between jaw crusher and gyratory crusher Any of you that are at all familiar with the Gyratory crushers and Cone Crushers that the former are used as Primary crushers will probably note many similarities between the types Each use a cone shaped crushing surface, and the same principal in the eccentric is employed to develop the crushing action requiredGyratory Crusher Cone Crusher Mantle Differences

Cone and gyratory crushers

Cone and gyratory crushers Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Cone and gyratory crushers, quarry, aggregate, and different kinds of mineralsA gyratory cone crusher of the type having a crusher head assembly mounted on an intermediate member supported for rotary motion on a shaft to produce gyratory motion of the crusher head assembly within a bowl assembly The intermediate member including a skirt surrounding the shaft and a stub shaft of reduced diameter extending upward above the shaftUSA Gyratory cone crusher Google PatentsThe gyratory crusher has capacities starting from 1200 to above 5000 t/h To have a feed opening corresponding to that of a jaw crusher, the primary gyratory crusher must be much taller and heavier Therefore, primary gyratories require quite a massive foundation The cone crusher is a modified gyratory crusherCone Crusher an overview ScienceDirect Topics

Gyratory Crusher l Introduce, Working Principle JXSC Mine

Gyratory Crusher VS Cone Crusher 1 The two cone shapes of the gyratory crusher are steeply inclined The movable cone is upright, and the fixed cone is an inverted truncated cone which in order to increase the need for feeding ore Nevertheless, cone crusher has two cone shapes, which are gently inclined, vertical frustum cone There is a Cone crushers resemble gyratory crushers from technological standpoint, but unlike gyratory crushers, cone crushers are popular in secondary, tertiary, and quaternary crushing stages Sometimes, however, the grain size of the processed material is small enough by nature and the traditional primary crushing stage is not neededCrushers All crusher types for your reduction needs 511 Cone crushers Cone crushers are commonly used for secondary, tertiary and quaternary crushing duties Two variations are available standard and short head The chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangement of the mantle and the cone at the discharge end in the cone crusherTECHNICAL NOTES 5 CRUSHERS

Cone and gyratory crushers

Cone and gyratory crushers Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Cone and gyratory crushers, quarry, aggregate, and different kinds of mineralsA gyratory cone crusher of the type having a crusher head assembly mounted on an intermediate member supported for rotary motion on a shaft to produce gyratory motion of the crusher head assembly within a bowl assembly The intermediate member including a skirt surrounding the shaft and a stub shaft of reduced diameter extending upward above the shaftUSA Gyratory cone crusher Google PatentsThe cone crusher is preferably configured to crush rock, stone, ore or minerals A method of making or retrofitting a crushing device such as, for example, a cone USB2 Gearbox assembly for gyratory and cone

differences between cone crusher and gyratory crusher

Cone Crusher VS Gyratory Crusher JXSC Mine The cone crusher has 25 times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quickly Therefore, it is advantageous to the ore crushing, the crushing efficiency is high 2 Different applications In large quarries, gyratory Gyratory Crusher Cone Crusher Mantle Differences, Difference between jaw 511 Cone crushers Cone crushers are commonly used for secondary, tertiary and quaternary crushing duties Two variations are available standard and short head The chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangement of the mantle and the cone at the discharge end in the cone crusherTECHNICAL NOTES 5 CRUSHERSCone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers It is often the case that there will be only one crusher installed, and this will be referred to as the primary crusher Cone crushers are more often used for 2nd, 3rd 4th stage crushing steps (although not always)Cone Crusher Explained saVRee

Cone Crusher Working Principle Animation Engineering

Cone crusher and gyratory crusher work on the same principle Both have the same operation If cone crusher differs then it is only from crushing chamber Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones It breaks the rocks by The result is a growing array of gyratory and cone crusher tooling upgrades What we offer Gyratory and cone crusher tooling solutions developed with you in mind Count on our upgrade solutions to increase your safety during maintenance, improve your crusher reliability and reduce downtimeImprove safety and maintenance with our gyratory toolingFeb 27, 2014 mobilesThe QS441 features the worldleading CS440 gyratory cone crusher from Sandvik The "S" type can accept a feed size up to 90% larQS441 Gyratory Cone Crusher YouTube

Construction, Working and Maintenance of Crushers for

Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used as primary crushers In the secondary and subsequent stages, the material is further reduced and refined for proper size and shape, mostly based on specifications Most secondary crushers are cone crushers andCone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers It is often the case that there will be only one crusher installed, and this will be referred to as the ‘Primary Crusher’ Cone crushers are typically used for 2 nd, 3 rd 4 th stage crushing steps (although not always)Gyratory Crusher Explained saVReeJan 28, 2009 A gyratory crusher has a higher angle at the cone apex This provides a longer residence time along the crushing interface and is supposed to generate a smaller more consistent product Minerals have much more, probably much better, information on their website 28th January 2009, 0:44 #3Difference between Cone Gyratory Crusher

Gyratory Crushers SolidsWiki

A Gyratory Crusher is a large crushing machinery, using the gyratory sports in casing cone cavity of crushing cone to produce extrusion, fracturing and bending role to materials for crushing ore or rock of various hardnessGyratory crusher is composed of transmission, engine base, eccentric bushing, crushing cone, center frame body, beams, original dynamic part, oil cylinder, pulley Outotec has created new premium parts offering for 3rd party crushers called the Contender™ Series These highperforming parts fit also for some cone crusher and gyratory crusher models Many parts in the series have improved safety features and extended operational life In addition to parts, we offer the required services Parts for crushers OutotecCone and gyratory crushers Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Cone and gyratory crushers, quarry, aggregate, and different kinds of mineralsCone and gyratory crushers

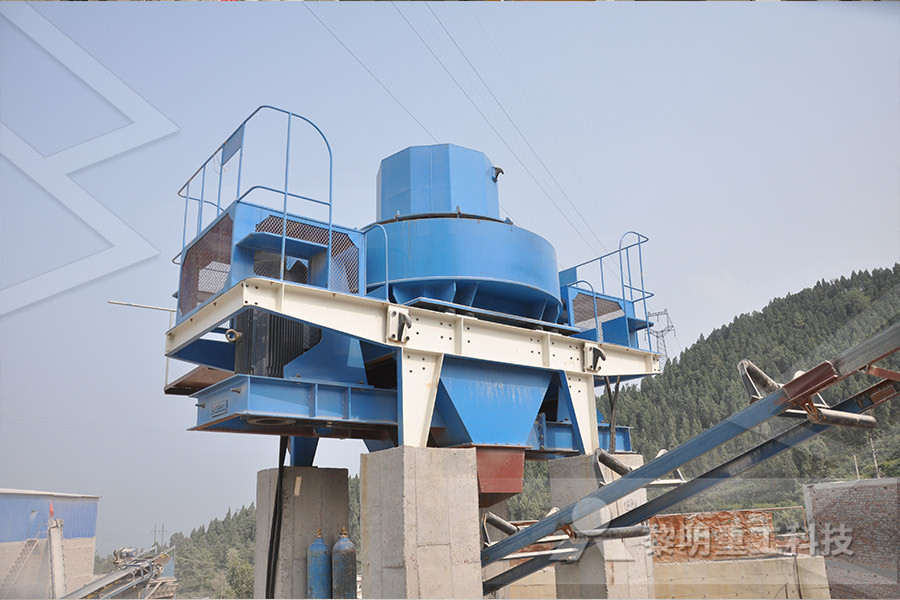

Gyratory Cone Crusher Manufacturer Propel Industries

Crushers GYRATORY CONE CRUSHER The Gyratory Cone Crusher delivers increased capacity with reduced maintenance and downtime It guarantees troublefree operation in varying feed conditions with a high reduction ratio It has large and stable feed opening, steep cavity and effective strokesThe cone crusher is preferably configured to crush rock, stone, ore or minerals A method of making or retrofitting a crushing device such as, for example, a cone USB2 Gearbox assembly for gyratory and cone Cone Crusher VS Gyratory Crusher JXSC Mine The cone crusher has 25 times higher rotating speed and 4 times larger swinging angle than the gyratory crusher, so the ore is impacted quickly Therefore, it is advantageous to the ore crushing, the crushing efficiency is high 2 Different applications In large quarries, gyratory Gyratory Crusher Cone Crusher Mantle Differences, Difference between jaw differences between cone crusher and gyratory crusher

Difference between Cone Gyratory Crusher

Jan 28, 2009 A gyratory crusher has a higher angle at the cone apex This provides a longer residence time along the crushing interface and is supposed to generate a smaller more consistent product Minerals have much more, probably much better, information on their website 28th January 2009, 0:44 #3The result is a growing array of gyratory and cone crusher tooling upgrades What we offer Gyratory and cone crusher tooling solutions developed with you in mind Count on our upgrade solutions to increase your safety during maintenance, improve your crusher reliability and reduce downtimeImprove safety and maintenance with our gyratory toolingCone crushers are a type of compression crusher used by aggregate, coal, concrete, crushing, fracking sand, and mining industries, which reduces material by squeezing or compressing it until it breaks By continuously optimization and innovation, we focus on improving product structure, upgrading raw material and optimizing assembly processCone Crushers Sandrock Mining

Construction, Working and Maintenance of Crushers for

Generally gyratory crushers, jaw crushers, high speed double roll crushers, low speed sizers, impactors and hammer mills are used as primary crushers In the secondary and subsequent stages, the material is further reduced and refined for proper size and shape, mostly based on specifications Most secondary crushers are cone crushers and Outotec has created new premium parts offering for 3rd party crushers called the Contender™ Series These highperforming parts fit also for some cone crusher and gyratory crusher models Many parts in the series have improved safety features and extended operational life In addition to parts, we offer the required services Parts for crushers OutotecMay 13, 2019 Setting cone and gyratory crushers The liner profiles are designed for a range of product sizes, from extra coarse to extra fine The extra fine liner profile will result in the highest fines proportion for a given cone crusher It’s important to find the Tips to maximize crushing efficiency Pit Quarry : Pit

Gyratory Crushers Diamond Equipment Group

Diamond supplies Trio Gyratory Crushers These crushers are a proven first stage of compression crushing for Large Mines and Quarries Mined ore or quarried rock can processed down to a size suitable for the secondary crushers Trio® TG Series Primary Gyratory crushers combine latest design together with innovative engineering, advanced technology and manufactureing []Gyratory Crusher – Traylor 1000 TPH Primary Gyratory Crusher 1000 TPH Primary Gyratory Crushing Plant Item #1 – FullerTraylor Model 4270 Type TCB Gyratory Crusher with cast steel two piece mainframe, 400 hp – 4,000 volt electric motor, direct shaft drive, hydraulic suUsed Gyratory Crushers for sale AllisChalmers equipment Gyratory And Cone Crusher Sciencedirect Jan 01 2016 primary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs basically gyratory crushers consist of a fixed solid conical shell or bowl also called concaves and a solid cone within the bowl called a breaking head figure 51the breaking head is fixed to a central spindle Difference Gyratory Crusher And Cone Crushercone Crusher

Construction of Gyratory Crusher

Installation of Gyratory crusher The crushing cone is mounted on the main shaft The upper end of the main shaft is suspended on the beam by a conical nut, a conical compression sleeve, a bushing and a support ring To prevent the cone nut from loosening, wedge keys are also installed on it