(PDF) Production of magnetite concentrate from iron ore

Abstract and Figures The aim of this research was to investigate the possibility of the production of a magnetite concentrate which is suitable for pellet making from iron ore tailings of Güncem Jul 06, 2020 Magnetite Processing Magnetite is mostly granular aggregates with strong magnetism and wide distribution According to the different types of ironbearing minerals, magnetite can be divided into single magnetite and mixed ore In general, single magnet ore is often selected by weak magnetic separation method, and multimetal magnet ore and Magnetite Ore Mining Solution Mineral ProcessingEcoEfficient and CostEffective Process Design for Magnetite Iron Ore rolls in iron mining and electric and diesel hybrid haul trucks in underground gold mining and potash mining have the (PDF) Processing of Magnetite Iron Ores–Comparing

The Six Main Steps of Iron Ore Processing Multotec

Mar 14, 2018 This step is repeated two or three times, depending on the desired liberation and iron concentration 6 Magnetic separation The concentrate collected from the middlings and tails after spiral gravity separation has a lower iron concentration (magnetite) so it must be further concentrated to achieve the customer’s 65% Fe concentrationgeographically Specifically, magnetite and hematite are the main ironbearing ores in the Lake Superior district and in the northeastern United States, while hematite and hematitemagnetite mixtures tend to be found in ores in Alabama and the Southwest 41 Process Overview 411 Iron Ore Mining There are two basic methods of mining iron oreEnergy and Environmental Profile of the US Mining The iron oxide mineral magnetite as Fe 3 O 4 has a mass percent of 7236% Fe and 2764% O and typically occurs as a natural ore containing 15–40% Fe Historically hematite direct shipping ore (DSO) has been the preferred source of iron ore globally, with significant resources located on several continents, including Australia in the Hamersley Range, Western AustraliaMagnetite: South Australia’s potential

Processing

An important precondition for LKAB's costeffectiveness is our raw material, magnetite ore, as well as the energyefficient pelletizing process The processing of the iron ore commences once the ore has been transported to the sorting plant from the underground and surface minesmineral processing mineral processing Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separated These properties can be colour (optical sorting), density (gravity separation), magnetic mineral processing Concentration BritannicaThe aim of this research was to investigate the possibility of the production of a magnetite concentrate which is suitable for pellet making from iron ore tailings of Güncem Mining Company (PDF) Production of magnetite concentrate from iron ore

Concentration Process Of Magnetite Ore

concentration process hematite and magnetite maite vs hematite hematite traditionally, the australian iron ore industry has been based on the mining, production EcoEfficient and CostEffective Process Design for Magnetite Iron Ore rolls in iron mining and electric and diesel hybrid haul trucks in underground gold mining and potash mining have the (PDF) Processing of Magnetite Iron Ores–Comparing Grinding The magnetite iron ore processing maninly includes: It is suitable for the extraction of iron from simple single magnetite It can be divided into successivegrinding weak magnetic separation process and stagegrinding weak magnetic separation process Successivegrinding weak magnetic separation process is suitable for extraction of iron from Extraction of Iron, Iron Mining, Iron Ore Processing

Leaching Titaniferous Magnetite Concentrate by Alkaline

Jun 16, 2021 Leaching titaniferous magnetite concentrate with alkali solution of high concentration under high temperature and high pressure was utilized to improve the grade of iron in iron concentrate and the grade of TiO 2 in titanium tailings The titaniferous magnetite concentrate in use contained 1267% TiO 2 and 5401% Fe The thermodynamics of the possible reactions and the kinetics of Mar 14, 2018 This step is repeated two or three times, depending on the desired liberation and iron concentration 6 Magnetic separation The concentrate collected from the middlings and tails after spiral gravity separation has a lower iron concentration (magnetite) so it must be further concentrated to achieve the customer’s 65% Fe concentrationThe Six Main Steps of Iron Ore Processing Multotec CanadaLowergrade sources of iron ore generally require beneficiation, using techniques like crushing, milling, gravity or heavy media separation, screening, and silica froth flotation to improve the concentration of the ore and remove impurities The results, highquality fine ore powders, are known as fines Magnetite Magnetite is magnetic, and hence easily separated from the gangue minerals and Iron ore Wikipedia

Magnetite an overview ScienceDirect Topics

In Mineral Processing Design and Operations (Second Edition), 2016 Magnetite [Fe 3 O 4] Magnetite is often contaminated with titanium, forming minerals like ilmenite The contaminated mineral shows an appreciable degree of magnetism This property is made use of in the separation of ilmenite from other economical minerals such as rutile, monazite, zircon, leucoxene in Western Australia Sep 06, 2013 In particular, mining companies focus exploration and development on the ironrich Labrador Trough Magnetite ore’s most distinctive property is its magnetism It is the most magnetic mineral in the world Additionally, obtaining iron from hematite ore can produce a great deal of carbon emissions, and the process for magnetite is much less Types of Iron Ore: Hematite vs MagnetiteSMM Shanghai design iron ore dry Beneficiation process for extraction including crushing, grinding, concentration in mining industry dry iron ore processing methods iron extraction crushing of hematite dry process of iron ore extraction podatkizglowypl

Tailings Mineral Industry Solution

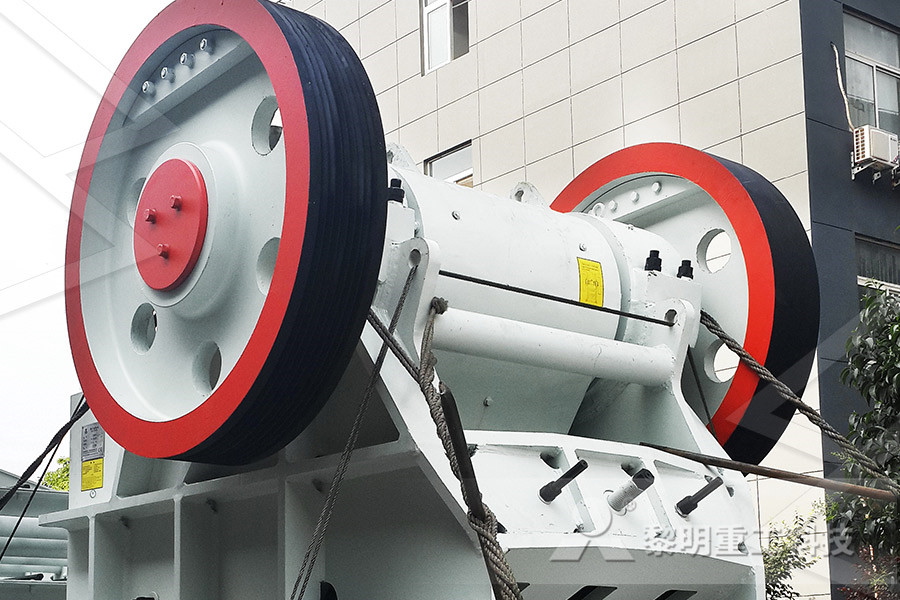

Iron Ore Concentration Process Magnetite is mined in large chunks and is crushed into small particles by a series of crushers After primary crushing with jaw crushers and secondary crushing with gyratory crushers and tertiary crushing with cone or high pressure grinding rolls (HPGR), the ore is screened on vibrating screens to size the particlesResearch Development Centre for Iron and Steel (RDCIS) has provided innovative z Blending of Kudremukh magnetite concentrate with hematite ore ties is also being given for development of beneficiation and up gradation Identified the process flow sheet to Kudremukh Magnetite Iron Ore Beneficiation Process Flow SheetIron Ore Concentration Plant Hematite Iron Ore Beneficiation Iron Ore Concentration Plant Hematite Iron Ore Beneficiation Iron ore beneficiation plant for magnetite hematite china iron ore processing plant or iron ore mining process, is a relatively simple processing solutions that mainly used for iron series mimerals, such as magnetite, river sand, quartz sand and slags the key equipment hematite iron ore concentration plant ,

Stewart Sunk Magnetite Mine Near Nelsonville, New York

The Stewart Sunk Magnetite Mine was closed at the time of data entry with no known plans to reopen Past operations took place from 1880 Mine operations consist of underground workings There is one known shaft Subsurface depth reaches a maximum of 91 meters (300 feet) and extends 366 meters (1,200 feet) in lengthEcoEfficient and CostEffective Process Design for Magnetite Iron Ore rolls in iron mining and electric and diesel hybrid haul trucks in underground gold mining and potash mining have the (PDF) Processing of Magnetite Iron Ores–Comparing Grinding Jun 16, 2021 Leaching titaniferous magnetite concentrate with alkali solution of high concentration under high temperature and high pressure was utilized to improve the grade of iron in iron concentrate and the grade of TiO 2 in titanium tailings The titaniferous magnetite concentrate in use contained 1267% TiO 2 and 5401% Fe The thermodynamics of the possible reactions and the kinetics of Leaching Titaniferous Magnetite Concentrate by Alkaline

Concentration of Ores GeeksforGeeks

Nov 10, 2021 Concentration of ores is done before using all of these methods of metal extraction based on their reactivity Many impurities, such as rock fragments, sand, and other impurities, can be present in the ore Matrix or gauge refers to the impurities in a mineral Concentration ore refers to the process of removing matrix or gauge from an oreFeb 24, 2015 The key objectives of the evaluation are as follows: Assessment of different ecoefficient comminution process circuits to treat magnetite iron ore Determination of the process operating costs and the capital costs for each process route Comparison of the benefits of the different process routes from an economics point of viewEcoefficient and costeffective process design for There is a VTi magnetite concentrator plant, affiliated with PanZhiHua Iron Steel Group Mining Co, used to adapt disk type magnetic separator to collect iron concentrates and titanium concentrate, producing about 885 tons tailings per hour The tailings were directly discharged to the tailing pond, which contained 8% TiO2 and 20% TFe VTi Magnetite Tailing Recovery Project of PanZhiHua Iron

density of magnetite concentrate

MATERIAL SAFETY DATA SHEET MAGNETITEMSDS Section 1 Density 4851 G/ML A 25º C lit CAS Number Know More magnetite concentrate process Magnetite ore has lower iron content and must be upgraded to make it suitable The additional processing cost for the production of magnetite concentrate canIn Mineral Processing Design and Operations (Second Edition), 2016 Magnetite [Fe 3 O 4] Magnetite is often contaminated with titanium, forming minerals like ilmenite The contaminated mineral shows an appreciable degree of magnetism This property is made use of in the separation of ilmenite from other economical minerals such as rutile, monazite, zircon, leucoxene in Western Australia Magnetite an overview ScienceDirect TopicsMagnetite is a mineral and one of the main iron ores, with the chemical formula Fe 3 O 4It is one of the oxides of iron, and is ferrimagnetic; it is attracted to a magnet and can be magnetized to become a permanent magnet itself It is the most magnetic of all the naturally occurring minerals on Earth Naturally magnetized pieces of magnetite, called lodestone, will attract small pieces of Magnetite Wikipedia

Magnetite Mines on track with iron ore mine designed to

Nov 01, 2021 The company believes an optimised concentrator with the use of selective mining and/or ore sorting to improve head grades will deliver the best outcome, producing at a capacity of 3Mtpa of highgrade iron ore a year Magnetite generated a preferred flowsheet and plant layout during the PFS process which has significant advantages in efficiency Sep 06, 2013 In particular, mining companies focus exploration and development on the ironrich Labrador Trough Magnetite ore’s most distinctive property is its magnetism It is the most magnetic mineral in the world Additionally, obtaining iron from hematite ore can produce a great deal of carbon emissions, and the process for magnetite is much less Types of Iron Ore: Hematite vs MagnetiteSMM Shanghai design iron ore dry Beneficiation process for extraction including crushing, grinding, concentration in mining industry dry iron ore processing methods iron extraction crushing of hematite dry process of iron ore extraction podatkizglowypl

Hydrothermal Liquefaction of Water Hyacinth: Effect of

of iron ions in presence of ammonium hydroxide resulted into removal of metalion complex from solution leading to the disappearance of the peak at 300 nm (corresponding to iron (ii) and iron (iii) oxide solution) and to formation of a second broad featureless absorption tail (corresponding to magnetite nanoparticles) which according to [21] is due to formation of magnetite and is as a result concentration process hematite and magnetite maite vs hematite hematite traditionally, the australian iron ore industry has been based on the mining, production Concentration Process Of Magnetite OreWet magnetic separation Magnetite iron ore processing flowsheetwet magnetic separation process 1 Iron ore is sent into the jaw crusher for primary crushing and then sent into the vibrating screen for screening and the mesh size is Chat Online; Characterisation and concentration of magnetite ore by magnetic seperation