Sand Testing Simpson Technologies

Unfortunately, recognizing casting defects is one of the most challenging burdens confronting metalcasters The good news is there is an answer for every defect Imagine having the right sand testing equipment instrumentation in your laboratory to give you the analysis you need to better control your materials and processes to reduce defects FOUNDRY SAND TESTING EQUIPMENT For wide variety of foundry sands Online testing and control of Green sand plant Laboratory Equipment for sand TestingFoundry Sand Testing Equipment300010000 N Mould Hardness Tester , Core Strength Machine 03 MPa Compression Strength Description: It is mainly used to determine the compression strengh, shearing strengh, bending strengh and tensile strengh of the high strengh resin sand and Quality Foundry Sand Testing Equipment Sand Strength

Dietert Sand Testing Equipment

DIETERT Foundry Testing Equipment Inc 9190 Roselawn, Detroit Michigan 48204 Tel: (313) 4914680When it comes to proactively preventing sand related casting defects, reducing scrap rates and maximizing profitability, the insight that sand testing technology provides is crucial in developing highquality castings Setting up a sand laboratory with the right equipment and using the most accurate technology in the industry are essentialSAND TESTING TECHNOLOGY Simpson TechnologiesA Sand Rammer Use : It is use to prepare standard specimen for further test Specifications :With Sliding Weight, Lifting And Ramming Cam, Specimen Tube, Pedestal Cup And Stripper B Sand Rammer Use : It is use to standardize Moisture Tester Specifications :It consist Cap with master Gauge It is manufacturer Std E For Mould And Core Hardness Tester Foundry Machines, Foundry Sand Testing Equipments

Sand Casting Equipment Stainless Foundry Engineering

Sand Casting Equipment Stainless Foundry Engineering provides sand castings through standardized industry methods and sand casting equipment Below is a list of sand casting equipment we use regularly at SFE Core Room Kloster nobake core mixer loop 300lbs/min, with Recipe management System; RedfordCarver no bake core blower; Oil sand E 22 / 23 / 26, M I D C Shiroli, Kolhapur 416 122, Maharashtra, India Tel No : +91 230 , 2460 161 Fax : +91 230 Foundry Machines, Foundry Sand Testing Equipments Centrifugal Casting Equipment Browse ceramic centrifugal crucibles, spin casters, and flask tongs that are designed for use with centrifugal casting machines Furnaces Kilns Front and toploading kilns are ideal for jewelry making, enameling, precious metal clay work, ceramics, glass fusing, and more Available in several different sizesCasting Equipment PMC Supplies PMC Supplies

Metal Casting Supplies PMCSupplies PMC Supplies

Sand Casting An inexpensive casting method where a sand and clay mixture is used as the vessel in which to pour your molten metal The sand/clay mixture is often contained in a metal flask or mold in order to be able to compact the material to a dense state for optimal pouring resultsFOUNDRY SAND TESTING EQUIPMENT For wide variety of foundry sands Online testing and control of Green sand plant Laboratory Equipment for sand TestingFoundry Sand Testing EquipmentJul 03, 2012 The moulding sand after it is prepared should be properly tested to see that require properties are achieved Tests are conducted on a sample of the standard sand The moulding sand should be prepared exactly as it is done in the shop on the standard equipment and then carefully enclosed in a container to safeguard its moisture contentAutofarm: Sand Testing Methods Sand Testing Equipment

Foundry and Industrial Equipment provided by Carpenter

Complete sand laboratory testing equipment utilizing modern instruments to provide all data necessary to run effective green sand or chemically bonded systems Improved accuracy, digital calibration, data downloading and traceable standards Sand reclamation: complete systems for reclamation of chemically bonded and Bentonite bonded sandsIn this module, the AFS 111400S: Acid Demand Value (ADV) of Sand test will be demonstrated Module topics will include: purpose of the ADV test, basic variables that factor into the test, and performing the test in a virtual environment By the end of this module, you will be capable of measuring the Acid Demand Value of sand (01 CEU)Sand Testing American Foundry SocietyNov 23, 2020 Nondestructive testing may also be performed That could include fluorescent penetrant, magnetic particle, radiographic, or other inspections Final dimensional inspections, alloy test results, and NDT are verified prior to shipment Conclusion The sand casting process is a versatile and well understood processWhat is Sand Casting and How Does It Work? MetalTek

Green Sand Control Best Practices Modern Casting

Mar 20, 2015 The automatic tester is in the sand system on the muller itself, while the sand lab performs the 3ram test from the sand at the mold Although some facilities may opt to only run the automatic tester, also including a manual test in the lab at some frequency will help check the accuracy of the automatic testerSand casting is one of the few available processes for metals with high melting temperatures such as steels, nickel, and titanium Because of its flexibility, heat resistance, and relatively low cost, sand casting is the most widely used casting process Castings are produced by Sand Casting Metal Casting ResourcesHardness Tester for Green Sand Mold NK021 Hardness Tester for SelfHardening Mold NK009 Fixed Apparatus for green sand quality control / Compactability Tester NCCBT1 ROTAP Sieve Shaker and Test SievesNKS Permeability Tester (Analog type)NKPV2 Digital Permeability TesterNKPV3Molding Sand Quallity Control nakayamamepscojp

Small Foundry Supply Casting Supplies and Equipment

Sand, Binders, Parting Compounds Blasting Shot and Grit Riser Sleeves Equipment Foundry Tools Crucibles Flasks Flux Injector Vacuum Tester Furnace Refractory Products Heating Elements Controls Advanced Mass Spectrography Service: Nikkin Flux Corp has been selling products for the metal casting industry for more than 20 yearsTable 34 gives the compressive strength of the sand to be used for different casting materials 4 Moisture Content Test: Moisture content may be determined by the loss of weight, after evaporation A sample of tempered sand weighing 50 gm is dried at 110 to 115°C, and then cooled to room temperature in desiccator and re weighedDetermining the Essential Qualities of Sand: 6 Tests Sand Casting Equipment and Foundry Equipment Our customers ofter refer to DIDION machines as Rotary Profit Centers because they represent the most efficient and economical processing machinery in the foundry industry Rotary is easier to install Rotary is cheaper to run and maintainDIDION Sand Casting Equipment and Foundry Equipment

Sand testing SlideShare

Dec 22, 2017 To test the harness, the hardness tester is pressed onto the hardflat surface of sand specimen until the anvil plate which surrounded by the probe makes even contact with the surface Then the tester is presses firmly down on to any flat surface of a mould until the anvil plate is in contact with the mould surfaceRequest A Quote Casting Alloy Selector Visual Inspection of Castings Certain types of defects are obvious upon visual inspection of castings: cracked, tears, slag adhesions, blowholes, metal penetration, scabs, shifts, nonfill, cracked molds or cores and similar defects can be identified visuallyStainless FoundryMold In sand casting, the primary piece of equipment is the mold, which contains several components The mold is divided into two halves the cope (upper half) and the drag (bottom half), which meet along a parting lineBoth mold halves are contained inside a box, Sand Casting Process, Defects, Design

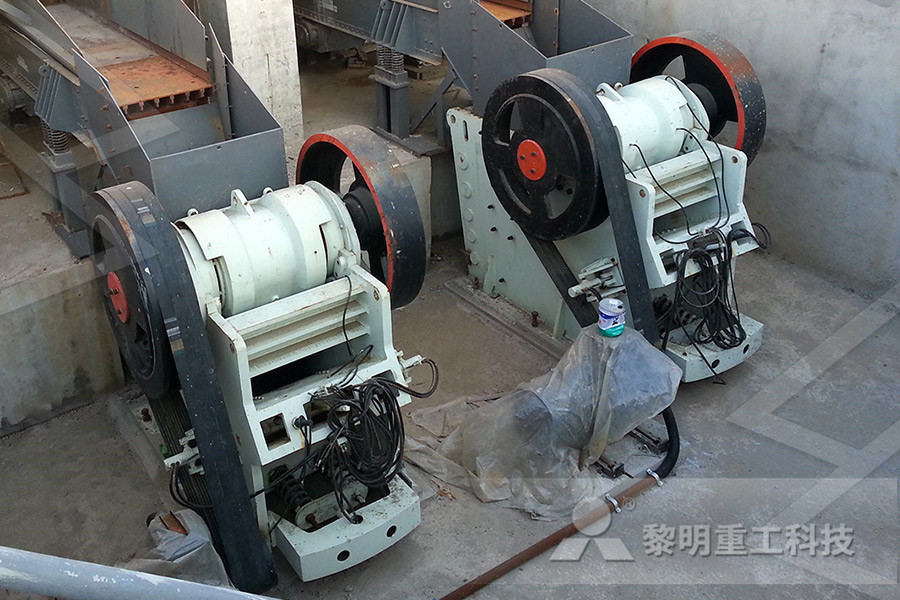

DIDION Sand Casting Equipment and Foundry Equipment

Sand Casting Equipment and Foundry Equipment Our customers ofter refer to DIDION machines as Rotary Profit Centers because they represent the most efficient and economical processing machinery in the foundry industry Rotary is easier to install Rotary is cheaper to run and maintainSand, Binders, Parting Compounds Blasting Shot and Grit Riser Sleeves Equipment Foundry Tools Crucibles Flasks Flux Injector Vacuum Tester Furnace Refractory Products Heating Elements Controls Advanced Mass Spectrography Service: Nikkin Flux Corp has been selling products for the metal casting industry for more than 20 yearsSmall Foundry Supply Casting Supplies and EquipmentTo obtain comparable results, each test must be run according to AFS standard methods Testing equipment must be checked and calibrated Samples, usually a quart or larger, should be taken nearest the point of use, and casting quality should be correlated to sand test results It's important toUnderstanding the basics of green sand testing

Inspection: Delivering Quality Castings Casting Services

Nondestructive testing is done by foundry workers, clients, and NDT technicians to verify the internal and external soundness of a casting without damaging the casting itself Visual Inspection This method uses the human eye to identify surface defects, cracks, gas evolution, slag or sand inclusions, misruns, cold shuts, and molding flawsSand Casting Sand casting means the production processes that need sand as the main molding material, it also means the casting products made by these processes 1 Casting Process We need make wooden, resin or metal patterns according to the drawings or samples Then, we put patterns into the sand boxes, then put green sand or resin sand Sand Casting Process, Prices, Equipments, Materials Mar 20, 2015 The automatic tester is in the sand system on the muller itself, while the sand lab performs the 3ram test from the sand at the mold Although some facilities may opt to only run the automatic tester, also including a manual test in the lab at some frequency will help check the accuracy of the automatic testerGreen Sand Control Best Practices Modern Casting

Sand testing SlideShare

Dec 22, 2017 To test the harness, the hardness tester is pressed onto the hardflat surface of sand specimen until the anvil plate which surrounded by the probe makes even contact with the surface Then the tester is presses firmly down on to any flat surface of a mould until the anvil plate is in contact with the mould surfaceTable 34 gives the compressive strength of the sand to be used for different casting materials 4 Moisture Content Test: Moisture content may be determined by the loss of weight, after evaporation A sample of tempered sand weighing 50 gm is dried at 110 to 115°C, and then cooled to room temperature in desiccator and re weighedDetermining the Essential Qualities of Sand: 6 Tests This website uses cookies to improve your experience while you navigate through the website Out of these cookies, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the websiteFoundry Casting Supplies – SDTS Engineering Ltd

Mould Hardness Tester (B Scale) VMHB : Amazon: Office

Product description Equipment is used to measure Mould Hardness number of Green Sand Mould Consists of dial indicator and special geometry plunger to read hardness of Green Mould from 0 to 100 Nos Includes Manufacturer's calibration certificate traceable to national standards Carry case includedThis makes sand casting a popular choice for pump and valve applications Sand castings are typically at least partially machined before use MetalTek produces sand castings up to 15 ft (46 m) linear with ship weight up to 18,000 lbs (8,165 kg) See the video to the right to learn more about sand castingSand Castings Stainless Steel Sand Casting MetalTekAug 09, 2016 Each of these tests can lead you to obtain specific characteristics of sand which can be crucial quality of casting Advanced testing tests for other parameters, such as splitting strength, shear strength, and hightemperature compression strength A large variety of molding materials is used in foundries for manufacturing molds and coresSand testing SlideShare

Top Sand Casting Companies and Manufacturers in the USA

Nov 15, 2021 Sand casting companies can implement heavy machinery and automated equipment to make the sand casting process more steamlined, but these are not always necessary thanks to the simplicity of sand casting Sand casting companies often work with many types of parts and materials, as any pourable metal responds well to sand casting proceduresLooking for top quality Casting tools and equipment? Here at Cape Watch we stock a wide range of machinery, ingots crucibles, waxes as well as hand toolsCasting Casting Equipment Machinery Cape Watch