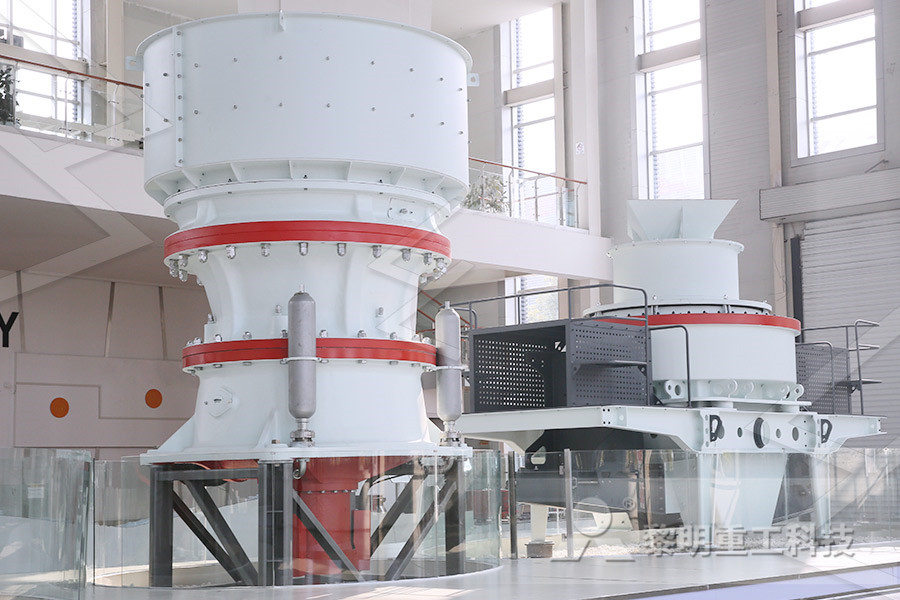

Ore Crushing and Grinding Facility Industrial Project

PROJECTS Ore Crushing and Grinding Facility Greenfield Sand Coating Plant Sand Coating Process Scrubber Installation Sand Plant Stack And Fan Replacement BLOG CONTACT US ORE CRUSHING AND GRINDING FACILITY Ore Crushing and Sep 09, 2016 The first stage of the crushing/grinding process in a production facility begins with blasting of the ore body, where the blasted material is composed of a very Crushing Grinding – The Anchor House, IncJul 08, 2019 In this sense, capacity of the primary crusher is indirectly increased thru higher equipment availability Some of the devices currently employed in large primary crushing plants are shown in Figure 1 In this particular primary crusher facility, mine run ore is trucked to a dump position from which the ore is fed by a pan feederInstrumentation and Automatic Control of Crushing and

BACKGROUND REPORT AP42 SECTION 1218 LEADBEARING

a description of the leadbearing ore crushing and grinding industry It includes a characterization of the industry, an overview of the different process types, a description of emissions, and a description of the technology used to control emissions resulting from leadbearing ore crushing and grindingOre Crushing and Grinding Facility Frances Ros T01:25:55+00:00 Ore Crushing and Grinding Facility Gallery Ore Crushing and Grinding Facility Greenfield Sand Coating Plant Frances Ros T01:59:31+00:00 Greenfield Sand Coating Plant GalleryHome Industrial Project SolutionsOre Crushing and Grinding Facility Frances Ros T01:25:55+00:00 Ore Crushing and Grinding Facility Gallery Ore Crushing and Grinding Facility Greenfield Sand Coating Plant Frances Ros T01:59:31+00:00 Greenfield Sand Coating Plant GalleryAbout Industrial Project Solutions

Explore a Metal Mine that Reports to the TRI Program US EPA

Sep 23, 2021 Crushing and Grinding At some facilities, mined ore undergoes crushing and grinding operations that reduce large blocks and fragments of ore to smaller sizes ranging from small rocks to sand The series of equipment used for Jul 08, 2019 In this sense, capacity of the primary crusher is indirectly increased thru higher equipment availability Some of the devices currently employed in large primary crushing plants are shown in Figure 1 In this particular primary crusher facility, Instrumentation and Automatic Control of Crushing and fine grinding Prior to grinding, the ore is drycrushed in up to six stages, depending on the hardness of the ore One or two stages of crushing may be performed at the mine prior to shipping the raw material to the processing facility Gyratory crushers are generally used for primary crushing, and cone crushers are1123 Taconite Ore Processing

Barite Ore Grinding Plant qualitygrinder

The facility provides rail and truck loadout facilities and two robotic bagging and palletizing lines for shipment of pallets by truck Barite ore grinding plant includes crusher, vibrating screen, jigging machine, and dewatering screen; sometimes it also needs ore washing machine and other equipmentFor crushing no grinding media is required, the ore size is reduced by external forces applied by the crusher Dry crushing but wet grinding Crushing is usually a dry process, while milling is performed with water The advantage of wet milling is the lower energy input compared to dry millingCrushing Vs Grinding MinerallurgyOre is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader The ore is conveyed, and lime is added (2) to raise the pH of the ore Following crushing through a jaw crusher (3), the ore is fed into the semi autogenous grinding (SAG) mill (4) along with water and steel ballsOre processing – Waihi Gold

The Six Main Steps of Iron Ore Processing Multotec Canada

Mar 14, 2018 Screening and diverting fine particles significantly increases the performance of the crusher 2 Crushing and stock piling This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground Once the ore has been crushed, it is diverted to a stockpile The aim of this step is to ensure a smooth crushing process May 04, 2018 https://zdzgcrusher/ballmillhtmlball mill is the key equipment for kinds of ores crushing and grinding It can be used for wet and dry grinding 10Crushing and Grinding of Ore YouTubeJun 21, 2019 According to the Coalition for EcoEfficient Comminution, comminution – the process of crushing and grinding ore – is by far the most energy consuming step in the mining process It Grinding down energy consumption in comminution

barite crushing and bagging facilities in houston tx

Mar 23, 2013 Bauxite ore crusher is major crushing fine grind barite 42 sg Mobile Crushing Plant barite grinding texas 2010 We grind barite and other industrial minerals at facilities in In mining industry, many stone crusher machines are at sale for different purposes, such as crushing machines, grinding mill machines, sand making machines and so on Phosphate Rock Crushing Plant In mining industry, there are many various processing plants with different output capacities for rocks processing, such as phosphate rock crushing Stone Quarrying Process LineClinker grinding stage: it adopts DPX crusher to crush plaster and cement clinker is premilled by roller press, hammer–mill crusher and XPCF crusher and then grinded by flour mill In the whole process, it may be seriously abrades steel ball, liner plate, grid plate is also specializing in manufacturing Big Gold Teeth hammer and rotor Cement Crushing Grinding Plant,

1126 Talc Processing US EPA

Talc ore generally is hauled to the plant by truck from a nearby mine The ore is crushed, typically in a jaw crusher, and screened The coarse (oversize) material then is returned to the crusher Rotary dryers may be used to dry the material Secondary grinding is achieved with pebble mills or roller mills, producing a productChrome Ore Crushing Plant dmcrusherandscreener 29/11/2017 Chrome Ore Crushing Plant; Chrome Ore Crushing Plant 29 Kasım 2017 yönetici Chrome ore mining and beneficiation is an important industry in some countries such like South Africa, Kazakhstan, India, Turkey and so on About 90% of the world’s chromite resources are concentrated in South Africa, Zimbabwe, the former Soviet Union and chrome ore crushing plant chrome ore crusher chrome ore Ore Crushing And Grinding Facility ore crushing and grinding facility industrial project Ore Crushing and Grinding Facility Frances Ros T01:25:55+00:00 Project Description Do You Have A Project We Can Help With? Get a free quote Contact us Filling out the form below will help us get you to the right group and a response as Crusher Ore Crushing And Grinding Facility Industrial Project

Instrumentation and Automatic Control of Crushing and

Jul 08, 2019 In this sense, capacity of the primary crusher is indirectly increased thru higher equipment availability Some of the devices currently employed in large primary crushing plants are shown in Figure 1 In this particular primary crusher facility, mine run ore is trucked to a dump position from which the ore is fed by a pan feederOct 01, 1998 The new roasting facility at Barrick’s Goldstrike Mine in Nevada, USA was developed to process 12,000 tons per day of refractory gold ore The process consists of crushing, dry grinding, roasting, extensive gas purification, calcine quenching, leaching in the presence of activated carbon and cyanide destructionDry Grinding at Barrick Goldstrike's Roaster FacilityPSE completed the design of a grassroots gold ore crushing and milling facility in Ocampo, Mexico as part of its strategic expansion program The implementation of the new facility helped the Ocampo mine increase gold production by over 50 percentGold Ore Crushing and Milling Facility PSE Consulting

Lihir Facts Processing Tripod

The primary crushing circuit incorporates a gyratory crusher to produce the required feed for semiautogenous grinding (SAG) Runofmine ore is delivered to the primary crushing facility by reardump haul trucks and frontend loadersOct 26, 2021 “The opportunity is to develop more energy efficient crushing and grinding processes that are integrated with a preconcentration capability, to remove as much barren material from the ore as possible prior to subjecting the remaining ore to energy and water intensive fine grinding and concentration processes,” Mr Revell explainedCSIRO spurs sustainable mining effortsClinker grinding stage: it adopts DPX crusher to crush plaster and cement clinker is premilled by roller press, hammer–mill crusher and XPCF crusher and then grinded by flour mill In the whole process, it may be seriously abrades steel ball, liner plate, grid plate is also specializing in manufacturing Big Gold Teeth hammer and rotor Cement Crushing Grinding Plant,

Cyanidation Process for Gold Extraction

It can be extended to service include ore haulage, crushing and conveying to surface for mineral processing base on contract mining Address:Kangqiao Industrial Area, Pudong, Shanghai Ph : (+86) 021 Email : 06, 2012 Jaw crusher for iron ore: Jaw crusher is used in primary crushing station It can crush iron ore into small sizes Thus, these small iron ore can enter into the iron ore mill such as ball mill for grinding impact crusher is generally used after jaw crusher, and can crush hard stones, not only the iron ore, but also other ores primary crushing iron oreThe Amax Buick facility was involved in crushing and screening, grinding and classification, lead and zinc selective flotation, thickening, and dewatering The system consisted of two cone crushers with related screens operating in closed circuit with the necessary conveyor belts to handle the oreDesign and installation of comminution circuits ostigov

Nickel Ore Processing Crusher, quarry, mining and

nickel ore processing plant The facility consists of a wharf for offloading nickel ore concentrate from bulk carriers, crushing and grinding facilities, a main processing plant approximately 2 Read moreMar 14, 2018 Screening and diverting fine particles significantly increases the performance of the crusher 2 Crushing and stock piling This step involves breaking up the iron ore to obtain an F 80 grind size before it can be ground Once the ore has been crushed, it is diverted to a stockpile The aim of this step is to ensure a smooth crushing process The Six Main Steps of Iron Ore Processing Multotec Canadaof the iron ore from the perspective of semiautogenous milling The CEET Crusher Index (Ci) is used to predict the SAG feed size distribution of the ore, and is measured during the SPI® feed preparation procedure It requires 10 kg of minus 2mesh material that is preferably prepared at the testing facility BOND BALL MILL GRINDABILITY TESTSGS MINERALS SERVICES – T3 SGS 960 112009

Grinding Mineral Processing

Grinding equipment for mineral processing The final fineness of the product mainly depends on the number of times the ore particles pass through the grinder The longer the grinding, the smaller the particle size Separate crushing and grinding steps are necessary, the ball mill can only receive the broken ore particle, and then grind to the