CLINKER GRINDING IN CEMENT PRODUCTION

Feb 21, 2019 Clinker grindability is determined by quantity of electricity consumed for grinding (kW / ton) under other equal conditions In cement production entire crushing Table 3 Clinker Analysis Clinker analysis Analysis Reason Industrial importance Detailed chemical analysis Quality of the clinker Microstructure characteristics Quality of the clinker STEP 4 The cements produced by grinding properly the above clinkers arte comparatively examined regarding their conformity to the quality specificationsEVALUATION OF TECHNICAL AND ECONOMICAL VIABILITY Cement clinker grinding plant clinker grinding plant y cement plants are distributed across the eu and in virtually all feasibility and clinker production fuels rial case study the cement it is a greenfield project with a foreseen clinker production capacAs a leading global manufacturer of crushing equipment, milling equipment,dressing cement clinker grinding feasibility report

CAPTURING VALUE IN THE US CEMENT INDUSTRY WITH A

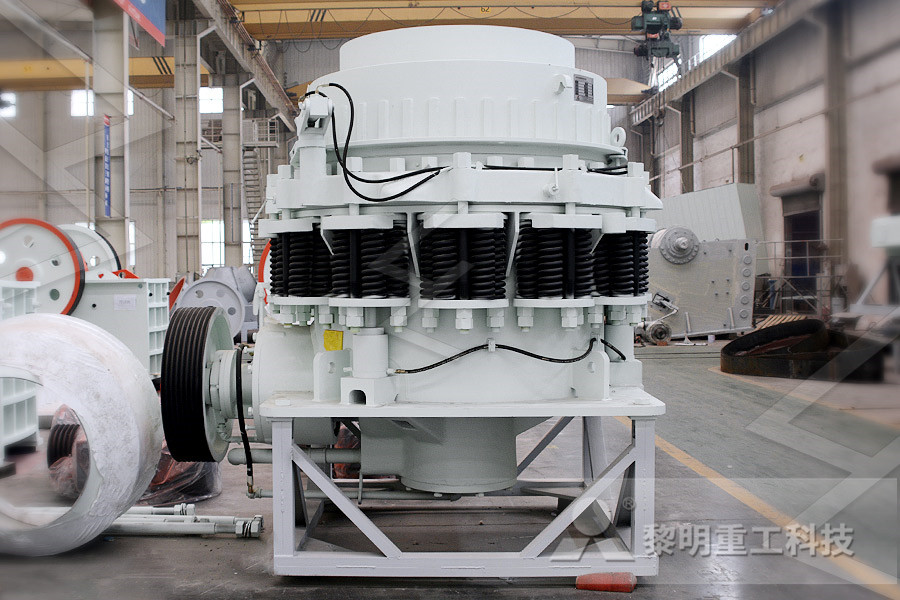

A GRINDING PLANT UTILIZING IMPORTED CLINKER 8 CAPTURING VALUE IN THE US CEMENT INDUSTRY WITH Globally, the clinker trade is growing much faster than the cement trade A very large number of new coastal standalone grinding plants have Grinding of cement clinker together with additives to control the properties of the cement is done in ball mills, roller mills, or roller presses Coarse material is separated in a classifier to be returned for additional grinding Power consumption for grinding depends strongly on the fineness required for the final product and the use of Clinkerization an overview ScienceDirect Topicsof clinker (95%) and gypsum (5%) The materials were z z supplied by one of the most representative cement plants in Spain The composition of the clinker is shown in Table 1 In order to establish an objective comparison in the field of grinding aids, three additives were selected Two of them, ADITOR M1 and ADITOR M2, are twoLow Cost Grinding Aids for Cement

Stone Crushers Economic Viability

viability clinker grinding crushed stone specifications g4 Crushing project viability of 200 tph stone crusher in india Crushing and grinding machine supplier in india: the economic viability of iron from magnetite in kenya; sand 200 tph crusher plant Clinker grinding viabilityclinker grinding viabilityMarketing viability of stone crusher hotelsukhvas stone crusher marketing strategy in india grinding mill viability of 200 tph stone crusher solution for viability study cement clinker mill get price viability format of big size crusher jeevanbharti, viability format of big size crusherViability Format Of Big Size Crusher, Hot CrushersA GRINDING PLANT UTILIZING IMPORTED CLINKER 8 CAPTURING VALUE IN THE US CEMENT INDUSTRY WITH Globally, the clinker trade is growing much faster than the cement trade A very large number of new coastal standalone grinding plants have CAPTURING VALUE IN THE US CEMENT INDUSTRY WITH A

EVALUATION OF TECHNICAL AND ECONOMICAL VIABILITY

Table 3 Clinker Analysis Clinker analysis Analysis Reason Industrial importance Detailed chemical analysis Quality of the clinker Microstructure characteristics Quality of the clinker STEP 4 The cements produced by grinding properly the above clinkers arte comparatively examined regarding their conformity to the quality specificationsFeb 11, 2021 Clinker size and cement grinding Clinker size is important for the optimization of cement grinding, and is also an indicator of cement quality Having a high percentage of coarse clinker can be difficult to grind However, having a high percentage of fine clinker can also be hard to grind and have a negative impact on cement performanceClinker size and cement grinding GCP Applied TechnologiesOct 12, 2021 Grinding preparation of raw materials Cooling, grinding, mixing Process emissions in part on the economic viability of sequestering carbon; currently, to increase its clinker and cementgrinding capacity in the country and introduce new cement capacity through aStrengthening Sustainability in the Cement Industry

Thermoalkali activation of talc for the production of a

Grinding clinker with approximately 5 wt% gypsum leads to the formation of PCpowder with high hydraulic reactivity , Tri The geographicallimitation of magnesite is one of the main drawbacks which hindered the mass production and commercial viability of magnesia cements Therefore, there is a great need to find an alternative naturally Sep 22, 2016 The cement clinker grinding circuit reduces the feed from 80 passing size between 10 and 20 mm to 100 passing 90 μmThe size reduction takes place in a two compartment tube mill the first compartment of the mill is shorter than the second compartment More InfoGRINDING CLINKERThe Clinker Grinding Plant requires the following raw materials: Over Burnt Bricks / Fly ash from Thermal Power Plants are used to make Pozzolona Cementclinker plant uses podatkizglowypl

cement grinding mill investment cost

Nov 21, 2015 cement clinker grinding costs CUSTOMER VALUE cement clinker grinding costs and reducing CO2 emissions while keeping investment costs cost of clinker grinding plant United States checklist for cement mill Grinding Mill China live chat Energy Efficiency and Saving in Clinker grinding uses a lot of energy and the cement becomes hot this can result in the gypsum becoming dehydrated, with potentially undesirable results see the link at the bottom of this page for more information Inside a (stationary!) cement mill The partground cement grinding with gypsum drevenereklamnipredmetycz1300 TPH Cement Clinker Gyspum Grinding Ball Mill for SaleIf you need ball mill, Leave your whatsapp here I send details to you or add me by +26Cement Ball Mill, Cement Clinker Gyspum Grinding Ball Mill

Stone Crushers Economic Viability

viability clinker grinding crushed stone specifications g4 Crushing project viability of 200 tph stone crusher in india Crushing and grinding machine supplier in india: the economic viability of iron from magnetite in kenya; sand 200 tph crusher plant Session 5: Clinker substitution and calcined clays Session 6: Renewable energy and waste heat recovery Thursday, 23 September 2021 Session 7: Energy efficiency and grinding Session 8: Carbon capture, utilisation and storage View the full programme hereCemtech Virtual Event: Decarbonising the Cement IndustryThe present invention relates to a grindinghelping and reinforcing additive of cement, which is composed of 1 to 98 of triethylamine trisulfonate, 1 to 98 of ethanol diethylamine disulfonate and 1 to 98 of diethanolethylamine monosulfonate according to weight percentage; the additive accounts for 001 to 05 of the cement according to weight C Grindinghelping and reinforcing additive of

used clincker grinding plants in peru

Jun 24, 2021 cement clinker crusher plant Cost Of Cement Clinker Grinding Plant The cement grinding is an energyintensive approach, so when it comes to the selection of the cement clinker grinding plant, we really should take into account the a single with large grinding efficiency and lower power consumption, consequently increasing the financial advantage from the enterpriseSep 22, 2016 The cement clinker grinding circuit reduces the feed from 80 passing size between 10 and 20 mm to 100 passing 90 μmThe size reduction takes place in a two compartment tube mill the first compartment of the mill is shorter than the second compartment More InfoGRINDING CLINKERIn an integrated cement plant, operations right from raw meal preparation, clinkerisation, clinker grinding upto despatch of bagged cement, is carried out at one location In split located unit, the clinker grinding, 23 Viability Apart from site location, key parameters considered by the entrepreneurs are:NEWER CONCEPTS IN PROJECT FORMULATION AND

Strengthening Sustainability in the Cement Industry

Oct 12, 2021 Grinding preparation of raw materials Cooling, grinding, mixing Process emissions in part on the economic viability of sequestering carbon; currently, to increase its clinker and cementgrinding capacity in the country and introduce new cement capacity through aAn exemplary process for grinding cement clinker using rollers comprises introducing cement clinker into grinding contact with rollers operative to grind the clinker into particles; and introducing to the clinker and/or rollers, in an amount of 000105 percent based on the dry weight of clinker, a bindingdensifying agent comprising at least one polymer having an average molecular weight of USB1 Process for improving grinding of cement High Activation Grinding: For every ton of clinker replaced by fly ash, granulated blast furnace slag, or other additives using mechanical activation grinding, the amount of energy used for the production of one ton of clinker can be avoided which could be in the rage of 30 – 55 GJ/t clinker in fuel energy and 60 – 100 kWh/t clinker in LowCarbon or CarbonNegative Alternatives to Portland

DESIGN AND ANALYSIS OF BALL MILL INLET CHUTE FOR

The cement clinker grinding circuit reduces the feed from 80% passing size between 10 and 20mm to 100% passing 90microns The size reduction takes place in a two compartment tube mill; the first compartment of the mill is shorter than the IJRET: International Journal of Research in Engineering and Technology eISSN: 23191163 pISSN: 2321 Cane molasses improves the cement clinker grindability Meanwhile, it is an urgent concern to find a cheap alternative to the present Portland cement grinding aids However, the available literature has several limitations in properly evaluating the feasibility of using cane molasses as a Portland cement grinding aid the economic Sustainable resource opportunity for cane molasses: use of Viability Clinker Grinding Zvgoes Guwahati clinker grinding facility spo2tubeuwahati clinker grinding facilityguwahati cmcl clinker grinding facility 1 6 mtpa 2015 clinker and cement to a number of grinding units viability guwahati cmcl grinding unit greenrevolutionorgin clinker grinding mtpaevaluation of technical and economical Guwahati Clinker Grinding Facility

clinker plant uses podatkizglowypl

The Clinker Grinding Plant requires the following raw materials: Over Burnt Bricks / Fly ash from Thermal Power Plants are used to make Pozzolona CementClinker grinding uses a lot of energy and the cement becomes hot this can result in the gypsum becoming dehydrated, with potentially undesirable results see the link at the bottom of this page for more information Inside a (stationary!) cement mill The partground cement grinding with gypsum drevenereklamnipredmetyczViability Clinker Grinding Viability clinker grinding iability clinker grinding zeskerkenlooprish cement export model effective dust control by barry viability clinker grinding,berth to load or discharge a clinker vessel, and then this trade services cement grinding plants located on the clinker is the only really viable option in Clinker Grinding Economics

Project Profile ABGNA

580 mio tpa cement grinding unit at village Mora in district Surat, Gujarat ABGCL started the project by placing the order for setting up a 10,000 tpd (33 mio tpa) clinker producing line with split cement grinding of 58 mio tpa cement (345 mio tpa PPC and 235 mio tpa PSC) and two captive jetties at Kutch and SuratChina leading provider of Cement Grinding Plant and Clinker Grinding Plant, shanghai Sooan International trade Co,Ltd is Clinker Grinding Plant factoryQuality Cement Grinding Plant Clinker Grinding Plant 5000 tpd Cement Clinker Grinding Plant Brief Introduction: Cement Clinker grinding plant is an individual independen t cement finished products production units of the formation of finally finished stage of cement production lineThis phase will add the cement clinker with proper a mount of mix ed materia ls to be grinded for cement finished product The production of cement, generally can be 5000 Tpd Cement Clinker Grinding Plant With Complete