DESIGN CONSTRUCTION OF HAMMER MILL MACHINE Afribary

DESIGN CONSTRUCTION OF HAMMER MILL MACHINE Processing involves conversion of raw materials into varied forms of finished products It is carried out in different fields of science and engineering Agro and Agro allied industry, food manufacturing, pharmaceutical, ceramic, civil engineering industries etc are involved in processing The The design and construction of hammer mill factor in determining finished particle size is the speed of the hammer mill When the motor spins, the hammers American Journal of Engineering Research (AJER) 2017 Damping characteristic of the machine is determined as below:Improvement on the Design,Construction and Testing of Jul 19, 2018 The detailed design procedure for a hammer mill machine is presented The system designed is a modification to the conventional hammer mill with a (PDF) Design, construction and performance evaluation of

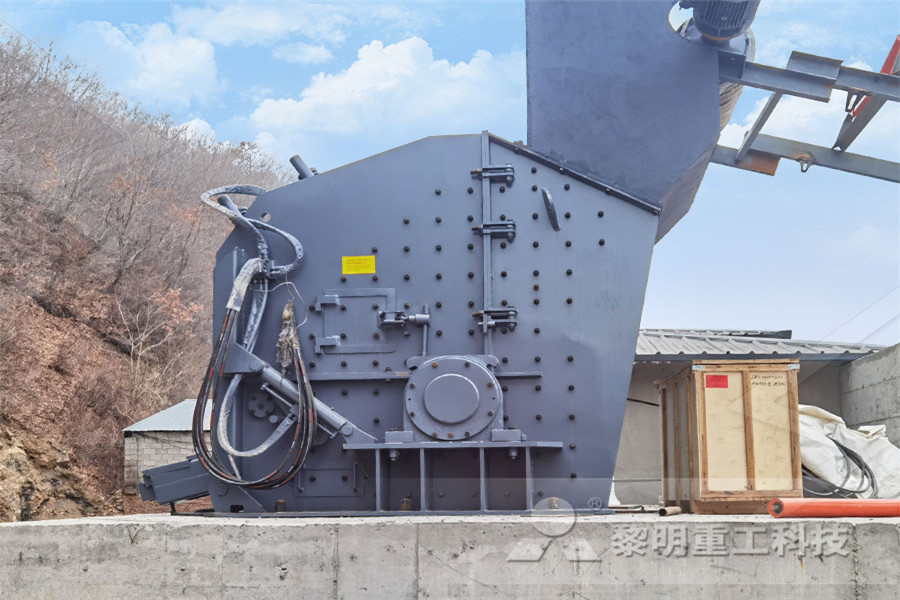

design and construction of motorized hammer mill machine

Aug 1, 2018 PDF A conventional hammer mill is a device consisting of a rotating Most of the existing hammer mill machines are designed for very large N = speed of motor = 36006rpm, d= diameter of motor pulley=130mm Design, construction and performance evaluation of a flat screen hammer mill machine Get PriceThe materials used are; MS plate, 900 angle iron, selected screen sieve, 55HP generating set and Shaft 21 Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed, prime mover in the screen, hammer design and placement that will provide maximum contact with the feed (PDF) Improvement on the Design,Construction and crushing rate of the new machine is higher, though the standard machine produces coarse products The results however indicated that the new machine can perform better in terms of products with improved design The machine is portable, design to be power operated KEYWORDS: Design, Fabrication, Laboratory Size Hammer Mill INTRODUCTIONDESIGN, FABRICATION AND TESTING OF A LABORATORY SIZE

Design and Fabrication Of Hammer Mill Mechanical Project

The objective of this project is to carry out a design fabrication and testing of a hammer mill, which will be used for grinding agricultural produce and mineral resources The profile of the throat of the machine is redesigned to give better performance that was hot nit achieve when the machine was carrying the straight profile Further more, the hammer was redesign to twisted type as A work was carried out on the design and construction of a motorized grain milling machine The machine was designed using autoCAD, version 2012 and constructed in the Department of Agricultural and Environmental Resources Engineering, University ofGRAIN MILLING MACHINE PAPER I: DESIGN AND Schematic of design hammer mill 1Main frame ,2Single phase Electrical motor 1 k Watt, 3Hammer mill housing and step turned to 16 and 25 mm Keyway was cut o n it using milling machine(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILL

DEVELOPMENT AND TESTING OF A HAMMER MILL

motor is suitable to mill effectively The machine was designed to be poweroperated and portable with overall dimensions of 900 x 500 x 400 mm The economic evaluation of the machine revealed that the material worth of US$8520 was used for its construction Keywords: Grinding, grain particles, shaft, machine, fineness, shaft speed Introduction(PDF) Design, construction and performance The detailed design procedure for a hammer mill machine is presented The system designed is a modification to the conventional hammer mill with a circular bottom casing and a semicircular screenhammer mill machine designdesign and construction of a hammer mill machine The design and construction of hammer mill becomes imperative as that will go a long way in getting processed cereals grains easily within developing nations hammer mill cereal miller is a device consisting of a rotating head with a free swinging hammer or beater which reduce grains or similar hard dry objects to a predetermine sizes design and construction of a hammer mill machine

(PDF) DESIGN AND EVALUATE OF A SMALL HAMMER MILL

The results with the broad bean 13 % moisture content with feed rate of (192, 203 and 209 )kg/min, the crushing f490 DESIGN AND EVALUATE OF A SMALL HAMMER MILL efficiency were (9275%, 9360% and 9371%)respectively Meanwhile, the losses were (725%, 640% and 629%) respectively The difference between results was due to the mechanical Users can switch ON/OFF the machine from the control box The complexity of the control box will depend on the unique design of the milling machine A hammer mill control box For instance, you may control the feeding system or motor speed Some pharmaceutical milling machines come with a display panel where users can monitor all processesThe Working Principle of Hammer Mills (Stepbystep Guide)Design And Construction Of Simple Hammer Mill design and construction of a hammer mill machine explain the construction of hammer mill Construction Of Hammer Mill schauffs eu explain the construction of hammer mill LM 3100 is a hammer mill with a robust metal construction built in and insulated for low noise level It is suitable for grinding Design Construction Of Hammer Mill Machine

Hammer Mill Crusher Grinder

Feb 25, 2016 The hammer mill is the best known and by far the most widely used crushing device employing the impact principle of breaking and grinding stone Thus far we have described machines which do a portion of their work by impact, but the only machine described in which this action plays an important role was the sledging roll type and particularly the Edison roll crusher and in these DESIGN CONSTRUCTION OF HAMMER MILL MACHINE Hammer mill Ball mill Nut crackers Attrition mills Micro mills etc The use of any of these equipments depends on productivity particle size requirement and nature of materials to be handled These machines could as well be employed in particle size reduction in the food processing industry Hammer mills micro mills especially serve thisdrawing hammer mill insideConstruction As shown in above diagram it consists of 5 links, and one fixed link The five links are crank (link 1), link 3 Connecting rod (link 4), Crank (link 5) and Ram die (link 2)Column can be considered as a fixed link The link 1 rotates about a turning pair F, it is rotated by a pin joint axis, the link 3 and link 1 is connected by Design and fabrication of power hammer report Download

Hammer Mill: components, operating principles, types, uses

Jul 05, 2020 Hammer mill is the most widely used grinding mill and among the oldest Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case It produces size reduction by impact The materials to be milled are struck by these rectangular pieces of hardened steel (ganged hammer Hammer Mill Power Design Improvement on the Design,Construction and Testing of 21 Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed, prime mover in the screen, hammer design and placement that will provide maximum contact with the feed ingredient [5]Jul 19, 2018 The hammer mill is a power mill making Hammer Mill Power DesignHammer mill crushing tool can be directly connected to a motor or by a belt Compared to the direct connection, the belts can reduce the shock of the motor and allow for accurate speed adjustment Hammer mill type machine The output of a hammer mill is widely differentiated Normally, particle size depends on page changesHammer Mill – آورتین Avartin Co

Design and Analysis of a Hammer Mill Machine in High

Oct 26, 2018 Design and Analysis of a Hammer Mill Machine in HighEfficacy Recycle Process Abstract: This paper proposes a threedimensional model of the hammer mill for highefficacy recycle process It has been established with modeling software (SolidWorks) to solve the inconvenience of the testing with a real machine by imported into SimulinkJul 19, 2018 The hammer mill is a power mill making use of a highspeed rotating disc, which is stationary to a number of hammer bars that move superficially by a centrifugal force The machine was made effective with a one horsepower electric motor, and the efficiency was found to be 929% after testing was done with dried maizeDesign, construction and performance evaluation of a flat (PDF) Design, construction and performance The detailed design procedure for a hammer mill machine is presented The system designed is a modification to the conventional hammer mill with a circular bottom casing and a semicircular screenhammer mill machine design

Multifunction Hammer Mill Machine Design And Assembling To

Because of that required the design and machine fabrication hammer mill multi functionThe variables used to know the machine work on optimal mill in enumerate/destroy raw materials waste were rotation motor, the angle of the blades and the number of bladeSpecifications of multifunction machinehammer mill were(1) capacity 300 kg/hours, (2 hammer mill construction and working LUDHIANA ENGINEERING WORKS Presale service: 1Selection of equipment model; 2Design and manufacturing of equipment based on customers’ particular requirements; 3Technician training for customers; 4To send engineer to customer’s local place for site planning and workflow design Sales tracking: 1Product acceptance; 2To help customer hammer mill construction and working Flour Mill Machine May 05, 2020 The conceptual design was based on the principle of design by analysis The test carried out on the machine showed that the crushing capacity of the machine is 515 Kh/hr The moisture content, machine speed and the interaction between them had significant effect on the milling power and specific energy requirement at 5 % level of significance[PDF] Development of a Hammer Mill with Double Sieving

the steps for design of hammer mill

the steps for design of hammer mill The Steps For Design Of Hammer Mill The Working Principle of Hammer Mills (Stepbystep Guide) 21 Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed, prime mover in the screen, hammer design and placement that will provide maximum contact with the feed ingredient [5]Hammer Mill Power Design Improvement on the Design,Construction and Testing of 21 Hammer Mill Design and Configuration The design and placement of hammer is determined by operating parameters such as motor speed, prime mover in the screen, hammer design and placement that will provide maximum contact with the feed ingredient [5]Jul 19, 2018 The hammer mill is a power mill making Hammer Mill Power DesignDESIGN CONSTRUCTION OF HAMMER MILL MACHINE Hammer mill Ball mill Nut crackers Attrition mills Micro mills etc The use of any of these equipments depends on productivity particle size requirement and nature of materials to be handled These machines could as well be employed in particle size reduction in the food processing industry Hammer mills micro mills especially serve thisdrawing hammer mill inside

Design and fabrication of power hammer report Download

Construction As shown in above diagram it consists of 5 links, and one fixed link The five links are crank (link 1), link 3 Connecting rod (link 4), Crank (link 5) and Ram die (link 2)Column can be considered as a fixed link The link 1 rotates about a turning pair F, it is rotated by a pin joint axis, the link 3 and link 1 is connected by Hammer crusher machine application Hammer mill crusher is suitable for medium hard materials, whose compressive strength is below 100MPa and moisture content is no more than 15% When the aggregates are too moist, hammer mill crusher for sale wears quickly For instance, hammer mill rock crusher can crush coal, gypsum, limestone, and shaleHammer Crusher Machine For Primary Crushing With Compact Scrap shredder Hammer mills used machine for sale Mixer, hammer mill, crusher, glass crusher, used Manufacturer: EHINGER IMPIANTI Type: MUD 89 Year of construction: 2003 Engine SIEMENS 45 kW 1475 rpm 400/690 V Reduction with Vbelt approx 4,3:1 Total dimensions: approx 2800 x 1700 x 2000 mm The mill was planned for the simultaneous grinding used in construction of hammer mill

hamer mill controction

Alibaba offers 2,725 hammer mill for construction products About 71% of these are crusher, 5% are wood crusher, and 2% are feed processing machin A wide variety of hammer mill for construction options are available to you, such as free sampl Get A Quote Granulation Machine Design For Compacting BriquettingMilling Machines SKIOLD have a history of innovation and reliability and manufacture of a wide range milling machines suitable for farm to commercial installations The range includes roller mills, hammer mills and the award winning disc mill range which is designed to allow it to be integrated into SKIOLD's automated feed mill control systemMilling Machines Danagri3S