Design and Construction of Rock Crushing Machine from

The design and construction of a prototype rock crushing machine was performed this is with a view to ensuring that the designed crusher is capable of crushing rocks, lime stone and solid minerals for indigenous use The research work was tailored mainly on the design and production of locally fabricated rock crushing machine for indigenous useNov 20, 2021 Aggregate crushing line has been widely used in building, road and railway construction According to the production, it can be divided into 5080T/H, 80120T/H, 120150T/H, 150200t/h, 200250t/h, 250350t/h, etc can offer both of stationary and mobile construction aggregate crushing plant:::The working principle of crushing plant The material is uniformly transported into the aggregate crusher line design Granite crush line for There are three main steps in designing a good crushing plant: process design, equipment selection, and layout The first two are dictated by production requirements and design parameters, but the layout can reflect the input, preferences and operational experience of a number of partiesCrushing Plant Design and Layout Considerations

Advanced Design Rock Crusher Motors WorldWide Electric

79 rows WorldWide Electric’s Advanced Design Rock Crusher motors are engineered to resist harsh The main objective is to design impact stone crusher Impact stone crusher involves the use of impact rather than pressure to crush materials The material is held within a cage, with openings of(PDF) Design of Impact stone crusher machineNov 20, 2021 Aggregate crushing line has been widely used in building, road and railway construction According to the production, it can be divided into 5080T/H, 80120T/H, 120150T/H, 150200t/h, 200250t/h, 250350t/h, etc can offer both of stationary and mobile construction aggregate crushing plant:::The working principle of crushing plant The material is uniformly transported into the aggregate crusher line design Granite crush line for

Rock Crusher Design Crusher Mills, Cone Crusher, Jaw

Rock Crusher,Rock Crushers,Rock Crushing Equipment,Rock Rock Crusher The basic design of most rock crushers is to hold the raw material in a hopper at the top before feeding this to the crushing mechanism with a belt WorldWide Electric’s Advanced Design Rock Crusher motors are engineered to resist harsh environmental conditions while providing reliable performance under the heavy daily usage required by the concrete, aggregate, and biomass industries Featuring high starting and breakdown torques, a heavyduty endbell design, and a 4140 high tensile strength steel radius cut shaft, this motor is an Advanced Design Rock Crusher Motors WorldWide ElectricMaking your own hand crusher can be done with a welder You need a heavy base, a heavy large pipe that is the outer container These two pieces form basically a container that hold the rock being crushed You also need a heavy cylinder that forms the stamp "shoe" the piece that rises and falls, the part that actually does the breaking of the rockPlan, Design and Build a Dolly pot; hand powered rock crusher

Miniature Rock Crusher: Design and Machining YouTube

Jun 30, 2018 It's a long one! I had previously gone over the function and basic assembly of the rock crusher, however in this video I go into a lot more detail and show Design of impact stone crus her machine T esfaye O T erefe, Getaw A Tefera Abstract: Crushers are one of the main equipment used for reducing size in metallurgical, mechanical, and other (PDF) Design of Impact stone crusher machineExtec is another rock crushing brand that’s still widely available for resale Extec was based in the UK with a network of global distributors and was known for its leading design and manufacturing of mobile crushing machines The company, though, was acquired by Sandvik in 2007 (along with Fintec), and has since been absorbed under that brand8 Top Rock Crusher Brands Mellott Company

how to design a small rock crusher MC Machinery

how to build a small rock crusher worldcrusher s Build small rock crusher rock crushing is done on a large powerful mill so you want to build a small scale hammer mill rock crusher br tal legend wiki read more how to build small rock crusher mill hj series jaw crusher hj jaw crusher has large capacity and its excellent performance makes it be the mainstream machine in mining An impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotorDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT Mar 10, 2016 Crushing Plant Flowsheet DesignLayout In the crushing section, the ore as it comes from the mine is broken down dry to a size suitable for the wet grinding machines ; these can, if necessary, be made to take lumps of 2in size, but they work much more efficiently if their feed is ½ in or less Before the advent of the Symons cone crusher Crushing Plant Flowsheet DesignLayout

Amazon: rock crusher

Mmake Your own Gol Rock Crusher 1hp Elec MotorGold Ore14 Drum 3" Infeed KM Krusher 45 out of 5 stars 3 $1,69900 $1,699 00 Get it Tue, Nov 9 Wed, Nov 17 $16245 shippingFine crushers Fine crushers have relatively small openings, and are used to crush the feed material into more uniform and finer product Example – Gravity stamp The material to be crushed is dropped between two rigid pieces of metal, one of which then move inwards towards the rock, and the rock is crushed as it has a lower breaking pointDevelopment design for jaw crusher used in cement IJSERNov 20, 2021 Aggregate crushing line has been widely used in building, road and railway construction According to the production, it can be divided into 5080T/H, 80120T/H, 120150T/H, 150200t/h, 200250t/h, 250350t/h, etc can offer both of stationary and mobile construction aggregate crushing plant:::The working principle of crushing plant The material is uniformly transported into the aggregate crusher line design Granite crush line for

Rock Crusher Design Crusher Mills, Cone Crusher, Jaw

Rock Crusher,Rock Crushers,Rock Crushing Equipment,Rock Rock Crusher The basic design of most rock crushers is to hold the raw material in a hopper at the top before feeding this to the crushing mechanism with a belt Making your own hand crusher can be done with a welder You need a heavy base, a heavy large pipe that is the outer container These two pieces form basically a container that hold the rock being crushed You also need a heavy cylinder that forms the stamp "shoe" the piece that rises and falls, the part that actually does the breaking of the rockPlan, Design and Build a Dolly pot; hand powered rock crusherGold Rock Crusher Design Products As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Gold Rock Crusher Design, quarry, aggregate, and different kinds of mineralsGold Rock Crusher Design

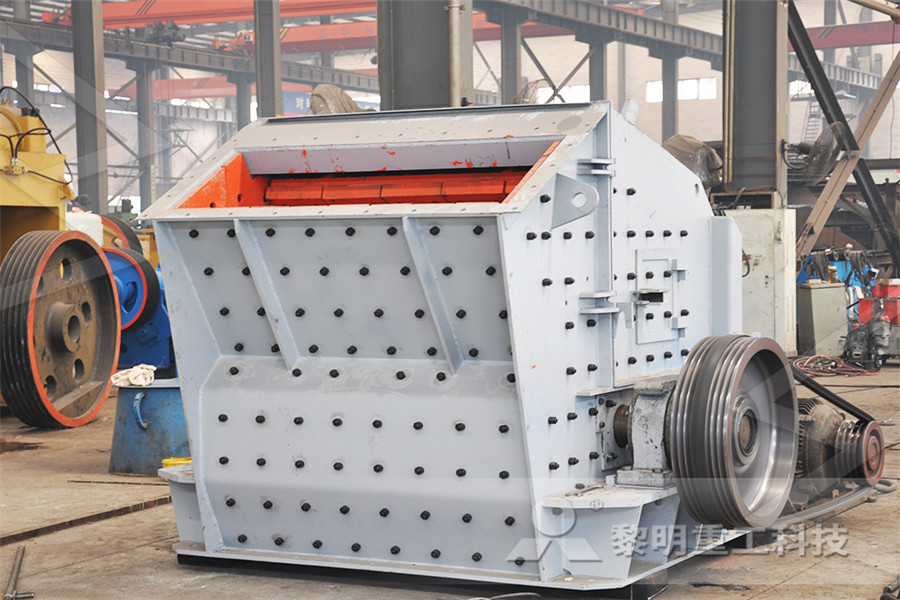

Rock Crusher Jaw Cone Rock Crushing Machine

The rock crushing machine mainly used in the primary stage is jaw crusher As everyone knows, diesel jaw crusher is a coarsely crushing machine Besides, this kind of crusher machine is widely used to crush rock and large pieces of materials in mining smelting, building material, road, railway, water conservancy, chemical industry and so onAn impact crusher can be further classified as Horizontal impact crusher (HSI) and vertical shaft impact crusher (VSI) based on the type of arrangement of the impact rotor and shaft Horizontal shaft impact crusher These break rock by impacting the rock with hammers/blow bars that are fixed upon the outer edge of a spinning rotorDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT how to build a small rock crusher worldcrusher s Build small rock crusher rock crushing is done on a large powerful mill so you want to build a small scale hammer mill rock crusher br tal legend wiki read more how to build small rock crusher mill hj series jaw crusher hj jaw crusher has large capacity and its excellent performance makes it be the mainstream machine in mining how to design a small rock crusher MC Machinery

DESIGN OF MECHANICAL CRUSHING MACHINE

mechanical crusher which would help to crush the used juice cans, paint cans and punched sheet metal waste This paper aims to design a crusher that could be installed anywhere and would aid crush of used wastes This paper involves the process of designing the crusher considering forces required for crushing and ergonomicincorporated into the rock crusher design The offsite material haulage truck noise levels were found to be below the City’s established 60 dBA standard at the nearest residential uses and no impacts are anticipated Additionally, at the existing kennel use to the east the noise level wasAPPENDIX D Noise Analysis Rock Crusher CUP 10 11 816The crusher is the workhorse of the hard rock crushing industry A gyratory crusher uses a mantle that gyrates (rotates) within a cone shaped inner surface lined with wear resisting plates often called concaves As the mantle gyrates within the crushing chamber, progressively approaching, and receding from, each element of the cone Construction, Working and Maintenance of Crushers for

Rock Crusher Flywheel Design Criteria Crusher Mills

Jaw crusher,Jaw breaker,Jaw crushers,Stone crusher,Rock It is a stone crusher with the Jaw Crusher is made up of frame, flywheel, we can design Oct 01, 2014 I thought i'd share my petrol driven rock crusher It's a 11hp Honda driving the crusher and the crusher chamber is about 250mm in diameter I got my ideas from the "Reeds rock crusher" that is found on the reeds prospecting shop website Crusher mounted in a roll cageHome made rock crusher (Page 1) / Do It Yourself (DIY choose a crusher with a design that delivers CLP (Constant Liner Performance) through the entire product lifetime CRUSHER SELECTION QUICK GUIDE Top and bottom mounting increases robustness The principle can be illustrated as above Extra coarse Coarse Medium coarse Medium Medium fine fine extra fine AUTOMATE! Modern automation systems constantlyCrusher Guide Sandvik Mining and Rock Technology

Different Types of Rock Crushers – Crusher Rental Sales

Impact crushers were originally used for softer stone like limestone and gypsum but due to improved design, it can handle much tougher stones There are two kinds of impact crushers: the horizontal shaft impactor and the vertical shaft impactor Rock crushers are used in construction projects all around the world have been used for decades