How to select equipment for underground mining

Nov 25, 2017 An indepth report on how to select equipment for underground mining along with necessary solutions provided T o meet the demand of coal in domestic market, Government of India (GoI) has set an ambitious target for the coal companies India’s demand for coal continues to increase to meet the needs of coalbased thermal power plants and the steel industry The coal mining industry accounts for about 80 percent of India’s demand for mining equipment used for open pit mines, which account for 90 percent of India’s mining operationsIndia Mining Mineral Processing Equipment Privacy ShieldJun 30, 2019 The most common types of mining equipment vary depending on whether the work is being carried out above or below ground or mining for gold, metals, coal or crude oil From drilling machines to excavators, crushing, and grinding equipment, the MINING Equipment List Mining Tools Names +

About Coal Mining in India SCCL

Jan 03, 2019 Selection of Rescue Brigades is done by conducting a written and practical test for 500 marks comprising: Educational Qualifications, Experience in mining Age, Experience in dealing mine emergencies as rescue trained and his seniority in rescue Technical knowledge in maintenance of apparatus and equipmentThe primary focus is focused on mechanization and automation of mining activities with the stateoftheart technologies in mining industry encompassing all methods of coal and noncoal mining (underground and opencast) in India and abroad The Mine Mechanisation Section facilitates multidisciplinary research in the following areas:Mine Mechanization And Technology DevelopmentUp to12%cash back Dikshit, MP, Singh, OP: Surface Miner operation – a cost effective, ecofriendly coal mining for mass production in opencast coal mines in India In: Procc of National Conference on Productivity Improvement in Surface Mines and Quarries – Role of New Technology and ancilliary Equipment, January 34, Organised by JMMF, Kolkata (2009 Blast Free Mining in Indian Surface Coal Mines – Current

Equipment Selection for Surface Mining: A Review

productivity In surface mining applications, the ESP addresses the selection of equipment to extract and haul mined material, including both waste and ore, over the lifetime of the mining pit In this paper, we focus speci cally on the truck and loader equipment selection problem for surface minesis most effectively used in mining equipment selection to analyse the earthmoving system, some equipment selection solutions exist that use simulation models Kannan et al (2000) recognise that despite the complementary role of academic research and industry applied simulation models, a gap exists between the two: academia followModels for Mining Equipment SelectionEquipment selection for high selective excavation surface coal mining by H Aykul*, E Yalcın†, IG Ediz*, DW DixonHardy‡, and H Akcakoca* Synopsis The choice of which mining method to use at many large surface coal mines is often dicated by what machinery is available or what experience the mine management can offer One of the mostEquipment selection for high selective T excavation

Longwall technology in india, SCCL

May 21, 2010 Longwall technology in india, SCCL 1 A PRESENTATION ON RETROSPECTIVE ASSESSMENT OF INDIAN LONGWALL MINING VNSPrasadM, UM(SCCL) USiva Sankar, UM(SCCL) Prof Mukhopadhyay S K, IIT, KGP Prof Debasis Deb, IIT, KGP Presented at 3 rd Asian Mining Congress, KolkataInvestment / Cooperation Opportunity in India ¾Development of UG projects with Longwall / mass production technology ¾Extraction of Pillars by Longwall / Shortwall tech ¾Manufacturer of spare parts for mining equipment in India ¾Technology for deep shaft sinking ¾Clean coal technologies: ¾UG Coal gasification ¾Coal liquefication ¾Setting up of washeryCOAL MINING IN INDIA : AN OVERVIEW EnergygovJan 03, 2019 Selection of Rescue Brigades is done by conducting a written and practical test for 500 marks comprising: Educational Qualifications, Experience in mining Age, Experience in dealing mine emergencies as rescue trained and his seniority in rescue Technical knowledge in maintenance of apparatus and equipmentAbout Coal Mining in India SCCL

coal mining equipment manufacturer in india – BEML India

Dec 18, 2018 A colossal land like India abounds in opportunities that a keen mining equipment manufacturer can exploit to the hilt Tapping naturally available resources and assets for the growth of the country necessitates use of machineries for different areas such as coal mining, diesel engine manufacturing, hydraulic excavation, etcJun 18, 2016 Such flexibility in mining operations has a significant impact on selection of technology and equipment Criticality of the selection of technology and equipment then brings focus back to Trends in Indian Mining Technologies and EquipmentCoal Lignite resources in India: Plan, Technology and Challenges for (201217) of Sub Group IV on Mining technology, Coal quality Beneficiation, Productivity, Automation Application of Information Technology, Formulation and Implementation of Coal Projects, Environmental Protection, Land acquisition, Rehabilitation and Resettlement (R R), Research Development, and Safety, Blast Free Mining in Indian Surface Coal Mines – Current

Highwall Mining in India SpringerLink

Highwall mining is a proven technology in USA and Australia to extract the blocked coal in thin nonworkable seams and the coal blocked in the highwall of opencast mines In USA, highwall mining contributes about 40 % share of total coal production In India, the highwall mining is Shakti Mining Equipments Private Limited is a renowned Manufacturer and Exporter of the widest range of Aggregate and minerals processing equipment mostly focusing on Crushing, Screening, Washing, Recycling and Material Handling Equipments covering a vast spectrum in Mining Construction Equipment field It is based in India since 1986 with Equipment Manufacturers in India Shakti Miningmining equipments selection This system is able to involve the expert knowledge in primary and secondary selection of equipment for surface coal mines [3] In 1990, another expert system, in order to classify equipment, was planned in the open pit coal mine of Britain with the help of fuzzy logicMethods for Equipments Selection in Surface Mining; review

Surface Mining Methods and Equipment

UNESCO – EOLSS SAMPLE CHAPTERS CIVIL ENGINEERING – Vol II Surface Mining Methods and Equipment J Yamatomi and S Okubo ©Encyclopedia of Life Support Systems (EOLSS) Figure 2 Change in production and productivity of US coal mines The higher productivity for open pit mining equipment also lowers costsSelection of overburden surface mining method in West Virginia used in WV surface coal mining in 2009 Considering an average price of blasting agents (bulk emulsions, slurry and material and it specifically addresses mining equipment such as electric and hydraulic shovels, and frontend wheelSelection of overburden surface mining method in West Nov 19, 2021 Coal and lignite firms plan to install an additional 5,560 MW renewable energy capacity by 2030 Economy India India's largest media on Indian EconomyCoal and lignite firms plan to install an additional 5,560

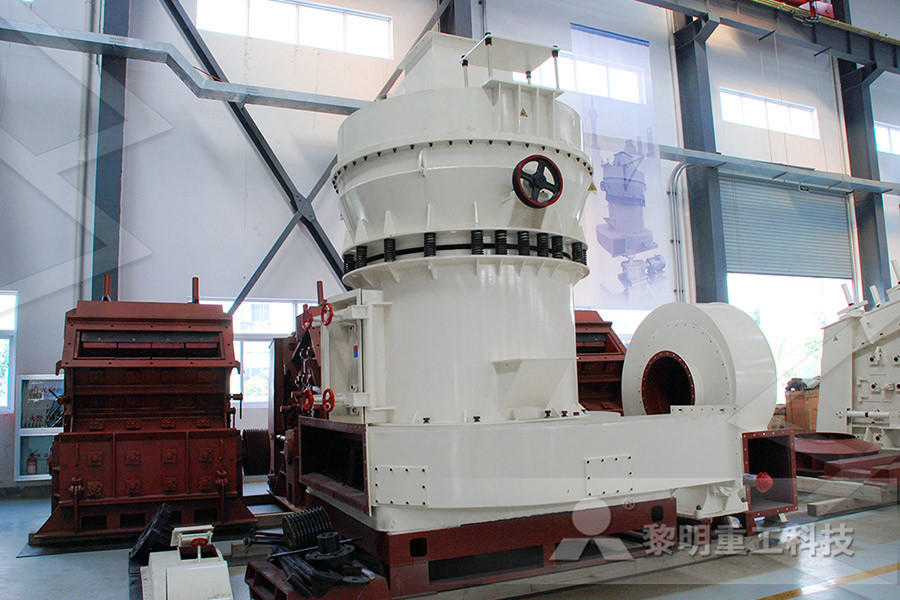

Coal Mining Equipment Manufacturers India

Coal Mining Equipment Manufacturers India FOB Reference Price:Get Latest Price Coal Open Mining Equipment Manufacturers India Photos Hydraulic cone crusher the latest generation of crusher in todays mining construction industry can replace spring cone crusher and general hydraulic cone crusher and it is ideal equipment in large stone plant and mining crushingIndia The growth narrative of the Adani Group has been in sync with the needs of the nation From pioneering the Mine Developer and Operator (MDO) model to providing endtoend mining solutions our vision is to make India selfreliant and reduce the dependency on importsMining India Adani Enterprises LtdOct 31, 2021 The average salary for a Mining Engineer in India is ₹526,557 to mining construction and are involved with capital/expense projects and equipment selection for the company's mining Mining Engineer Salary in India PayScale

COAL MINING IN INDIA : AN OVERVIEW Energygov

Investment / Cooperation Opportunity in India ¾Development of UG projects with Longwall / mass production technology ¾Extraction of Pillars by Longwall / Shortwall tech ¾Manufacturer of spare parts for mining equipment in India ¾Technology for deep shaft sinking ¾Clean coal technologies: ¾UG Coal gasification ¾Coal liquefication ¾Setting up of washerySep 10, 2020 350TPH Coal Crusher Plant in India How processing plant configurated, what equipments were used and how much cost? Read more350TPH Coal Crusher Plant in India JXSC MachineDec 14, 2018 It’s a random, just to give you the brief about the mining companies in India 1 Coal India (CIL) Coal India is the state government control company It headquarters in Kolkata, West Bengal It’s the largest coal producing company in the world Company contribute the 82% coal production in List of Mining Companies in India Heavy Equipments

Highwall Mining in India SpringerLink

Highwall mining is a proven technology in USA and Australia to extract the blocked coal in thin nonworkable seams and the coal blocked in the highwall of opencast mines In USA, highwall mining contributes about 40 % share of total coal production In India, the highwall mining is top 10 coal companies in india As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralstop 10 coal companies in indiaof improper equipment selection, nonavailability of spares and equipment itself and so many other factors But time has come now to shift our attention towards underground mining Need to develop underground mine mechanisation in India l Most of the underground mine in India is conventional and the resulting shortfall inune, 2018 Future of Bulk Production from Underground Coal

Coal and lignite firms plan to install an additional 5,560

Nov 19, 2021 Coal and lignite firms plan to install an additional 5,560 MW renewable energy capacity by 2030 Economy India India's largest media on Indian EconomyPlanning, Design Engineering, selection of necessary equipment and Machinery, Procurement, delivery, erection/installation, Testing, Successful Commissioning of 50 MTPA Coal washing Plant at Madhuband including performance guarantee Test with 2 years critical spares and all allied activities necessary to put the plant for commercial operationHeavy Engineering Corporation Limited, Ranchi, Indiasurface coal mining from shovel mining to dragline mining Coal India Limited (CIL), now has standardized the draglines in two sizes, namely 10/70 and 24/96 for their mines Most mines depend on the dragline 24 hours/day, 7 days/week In many of coal mines, it’s the only primaryCASE STUDY ON DRAGLINE

MASS PRODUCTION TECHNOLOGY

syllabus : status of coal mining in india and abroad, need for mass production technology for indian coal continuos mining technique : applicability, layout for development and depillaring, design, equipment required and their selection, system analysis, cycle of operation, case studiesWith teams based in major mining regions stretching across four continents, Mineral Technologies’ solutions incorporate metalllurgical testing, plant design and equipment supply – transforming ore bodies into valuable commodities for customers worldwide Recognised industry leadership Mineral Technologies has 30 years’ experience in IndiaMineral Technologies shares secrets of success in India Opencast coal mining in India is also to contribute the bulk output (over 90%) of coal with ecofriendly mining practices adoption of best technological option available in the globe needs It proper planning, appropriate technology adoption, suitable mechanization, Human Recourses Development to Technology and equipment selection for Department of Mining Engineering, IIT Kharagpur

Maximum Aerobic Capacity of Underground Coal Miners in India

Sep 25, 2011 Miners fitness test was assessed in terms of determination of maximum aerobic capacity by an indirect method following a standard step test protocol before going down to mine by taking into consideration of heart rates (Telemetric recording) and oxygen consumption of the subjects (OxylogII) during exercise at different working rates Maximal heart rate was derived as 220#x2212;ageIndia Coal Mining Line: The raw coal materials will be washed first for the next mining processing line Coal types of crusher plant are the second mining step for the whole production line Of course, the coal will be crushed and grinded through the crusher and mill machine Coal Washing Plant Used in India: Coal washing is an indispensable Various Types of Coal Crusher Plant India, Jaw Crushing