Mining and Processing Iron Ore Vulcan® Drying Systems

Drying Systems has designed and built plants for clients processing up to 450 tons per hour Drying is an important step in the iron ore process, reducing shipping and storage costs, while making the material easier to handle As an essentialTo efficiently process iron ore for high quality steel production, frequent ore grade monitoring, during all steps of downstream processing, is mandatory Independent from the ironmaking method, the optimal use of fuels and energy during sintering, pelletizing and direct reduction of iron ore (DRI) needs to be applied to stay competitive and Iron Ore Analysis Process Optimization Solutions Jan 01, 2015 Iron ore was won by drilling and blasting ()As mining technology generally developed, so did drilling techniques and the explosives used Smith (1990) reported that the Cleveland deposit was associated with a very strong stone roof rock (known as “dogger”) allowing mine drivages to be selfsupporting However, he states that in later years where the mining had progressed to the dip, this Iron ore extraction techniques ScienceDirect

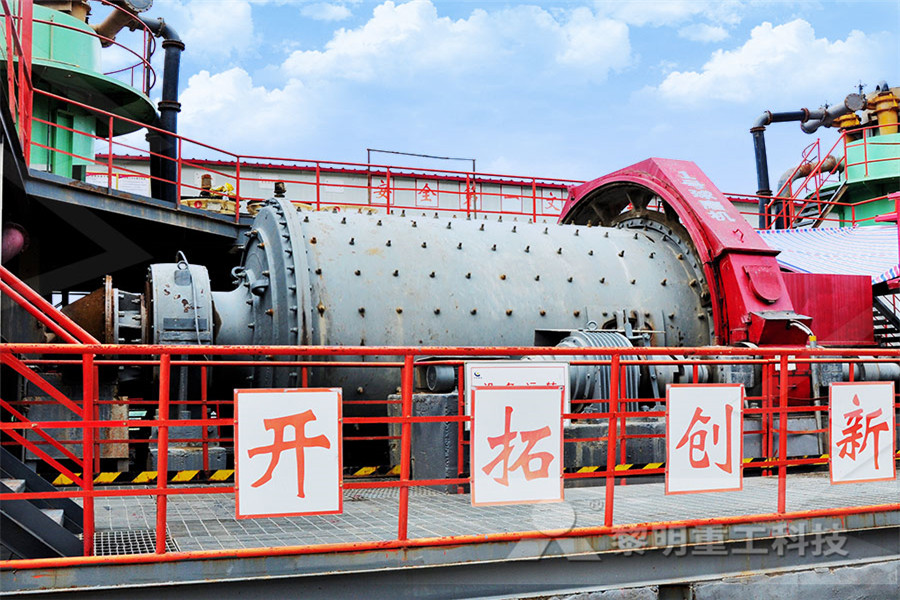

The Latest Developments in Iron Ore Processing

–Process 600t/h lumpy iron ore • DMS Cyclone –Only 6mm material for iron ore –360mm diameter cyclone –Process 40t/h per cyclone • Larcodems –90+6mm stones –12m diameter –Operating capacity of 600800t/h –Efficient separation at SG’s as high as 41g/cm3 Dense Media Separation on Iron Ore •iron ore processing technique systems; Mineral processing Wikipedia Dewatering is an important process in mineral processing The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported iron ore processing technique systemsIron Ore Processing Technique Systems Iron ore as a main dry cargo OpenSea Control of Pollution in the Iron and Steel Industry Iron processing Britannica Emerging iron ore producer Kogi Iron supplies Nigeria's Efficiently optimise ore sorting iron ore processing technique systems nigeria

iron ore and pellet processing systems Simurgh iron and

iron ore and pellet processing systems iron ore and pellet are made of iron ore and other additives that are first raw and then cooked and hardened; And it is used to revive the traditional method of iron production in blast furnaces or various direct reduction This process varies depending on the ore source, but typically involves various stages of crushing and grinding to reduce the size of the iron ore Separation techniques such as magnetic separation or froth flotation are then used to separate the gangue (unwanted) materials from the iron contentIron Ore Pelletization FEECO International Inciron processing iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is iron processing Ores Britannica

Quantitative Analysis of Mineral Composition of Iron Ore

Quantitative Analysis of Mineral Composition of Iron Ore Sinter Based on Comprehensive Image Processing Techniques Hongwei GUO,1,2)* Buxin SU,2) Zhenlong BAI,3) Jianliang ZHANG 2) Xinyu LI and Feng LIU2) 1) Shangang School of Iron and The ALS Iron Ore Technical Centre has been designed and built to accommodate scalable fused bead XRF processing capacity in excess of 10,000 samples per day With specialist expertise in processing hematite, magnetite and all forms of iron ore, the centre provides extensive ore characterisation,Iron Ore Technical Centre alsglobalMay 24, 2016 Beneficiation of Iron Ore and the treatment of magnetic iron taconites, stage grinding and wet magnetic separation is standard practiceThis also applies to iron ores of the nonmagnetic type which after a reducing roast are amenable to magnetic separation All such plants are large tonnage operations treating up to 50,000 tons per day and ultimately requiring grinding as fine as minus 500 Beneficiation of Iron Ore Mineral Processing Metallurgy

Find out more about the S11D project’s dry ore processing

Oct 02, 2015 Find out more about the S11D project’s dry ore processing technique In general, in order for iron ore to be sold, it needs to pass through equipment to break it down and classify it by particle size In this process, the materials go through screens, which separate them in line with standard product specificationsMay 26, 2016 New dry iron ore processing technology developed The mine tailing dam spill at BHP and Vale’s Samarco iron ore operations last year killed 19 people and had devastating effects on the New dry iron ore processing technology developed iron ore processing technique systems; Mineral processing Wikipedia Dewatering is an important process in mineral processing The purpose of dewatering is to remove water absorbed by the particles which increases the pulp density This is done for a number of reasons, specifically, to enable ore handling and concentrates to be transported iron ore processing technique systems

Iron Ore Analysis Process Optimization Solutions

To efficiently process iron ore for high quality steel production, frequent ore grade monitoring, during all steps of downstream processing, is mandatory Independent from the ironmaking method, the optimal use of fuels and energy during sintering, pelletizing and direct reduction of iron ore (DRI) needs to be applied to stay competitive and With 5 mines, 4 processing hubs and 2 port facilities, our Pilbara iron ore business is all connected by more than 1,000 kilometres of rail infrastructure At each mining hub ore from the mines is crushed, beneficiated (where necessary) and blended to create highgrade hematite lump and fines productsIron ore BHPLala Saha, Kuldeep Bauddh, in Phytorestoration of Abandoned Mining and Oil Drilling Sites, 2021 424 Iron ore mining Iron ore is another important mineral from which metallic iron is extracted The high demand for metal leads to continuous mining and processing, generating a large amount of solid and liquid waste From the beginning of extraction to processing and at the final stages, it Iron Ore an overview ScienceDirect Topics

AUB2 A process and system for dry recovery of

A PROCESS AND SYSTEM FOR DRY RECOVERY OF IRONORE FINES AND SUPERFINES AND A MAGNETIC SEPARATION UNIT A magnetic separation unit suitable for the separation of determined fractions corresponding to fine and superfine particles of oxidized iron ore, the magnetic separation unit comprising: a permanent high intensity raze earth roll magnetic separator operating with magnetic 3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~0074 mm) going to froth flotation cells for recovery of iron 4In magnetite processing plant,the process of flotation separation is replaced by magnetic separationextraction of iron, process of iron, iron processing, iron To efficiently process iron ore for high quality steel production, frequent ore grade monitoring, during all steps of downstream processing, is mandatory Independent from the ironmaking method, the optimal use of fuels and energy during sintering, pelletizing and direct reduction of iron ore (DRI) needs to be applied to stay competitive and Iron Ore Analysis Process Optimization Solutions

Dressing Ways for 3 Kinds of Iron Ore Make You Profitable

Jul 12, 2021 The following is a summary of the most powerful iron ore processing technologies, hoping you can get help: Magnetic iron ore Single magnetic ore Single magnetic ore is mainly embedded in fine grains Gangue minerals are mainly silicate minerals such as quartz and hornblende, some of which contain more iron silicateGrade Blending for Iron Ore Processing Akumen Offering a homogenous product to customers on time can be a challenge in the mining sector The grade of the ore differs across the deposit and can be well above or below the target grade range that was promised to the customer Blending ore of high and low grade can help to hit just the target Grade Blending for Iron Ore Processing AkumenThe ironore fines that enter the BF need to go through a pelletizing and sintering process In other cases, such as the smelting reduction (SR) processes that use the fluidized bed technologies the ironore fines can directly be charged into the reduction process making it highly advantageousIron Ore Reduction an overview ScienceDirect Topics

Quantitative Analysis of Mineral Composition of Iron Ore

Quantitative Analysis of Mineral Composition of Iron Ore Sinter Based on Comprehensive Image Processing Techniques Hongwei GUO,1,2)* Buxin SU,2) Zhenlong BAI,3) Jianliang ZHANG 2) Xinyu LI and Feng LIU2) 1) Shangang School of Iron and May 26, 2016 New dry iron ore processing technology developed The mine tailing dam spill at BHP and Vale’s Samarco iron ore operations last year killed 19 people and had devastating effects on the New dry iron ore processing technology developed Iron ore is then transported and shipped to milling plants This guide provides information on Standards, Certification schemes and other industry specific information that may be of interest to anyone working within the iron ore mining industry, including information relevant to mining, electrical, and civil/structuralGuide to Standards Iron Ore Mining SAI Global

Effective Beneficiation of Low Grade Iron Ore Through

Large numbers of iron ore mines are in operation in Orissa, India to meet the internal and export demand of iron ore for iron and steel making During the process of mining relatively lower grade iron ore containing 5658% Fe is also being generated and stockpiled separately due to less market and industrial value The accumulation of theseMar 30, 2020 The main aim of the present study is to investigate geochemical analysis of iron ore and ironenriched mineralised zones and their source identification by understanding lithological, structural and geomorphological units The geology, geomorphology and lineament maps were prepared with help of Landsat 8 OLI satellite data and prepared thematic layers in two mandals namely Geochemical characteristics of iron ore deposits and Assessing the Accuracy of Quantitative XRD with Aluminous Goethite MixedCrystal in Bauxite and Iron Ore Xray diffraction, also known as XRD, is a technique used for establishing ore mineralogy TOPAS quantitative phase analysis (QPA) combined with fast detectors integrated in the XRD systems enables rapid standardless analysisAssessing the Accuracy of Quantitative XRD with

Iron Ore production in the Pilbara Rio Tinto

Iron Ore production in the Pilbara Rail and port operations Rail Ore is railed up to 460 kilometres to the coast along a dedicated privately owned rail system A typical train consist comprises 2 GE Dash 9 locomotives, 230 ore cars and is over 24 kilometres long A single driver, supported by centralised track control, operates the trainIron Ore: Mineralogy, Processing and Environmental Issues summarizes recent, key research on the characterization of iron ores, including important topics such as beneficiation (separation and refining), agglomeration (eg, production of pellets or powders), blast furnace technology for smelting, and environmental issues relating to its productionIron Ore ScienceDirectVale’s iron ore fines production1 totaled 894 Mt in 3Q21, 181% higher than in 2Q21, as a result of: (i) seasonal improvement of weatherrelated conditions in Northern System, boosting Serra Norte and S11D performance; (ii) Vargem Grande production increase by dry processingVALE’S PRODUCTION AND SALES IN 3Q21

China aims to increase selfsufficiency on iron ore with

Jul 21, 2021 In light of this, a group of scientists has set the goal to increase selfsufficiency in iron ore The main reason behind China's dependency on imported iron ore is that the country's iron ore is relatively lowgrade and expensive to process Ever since 35yearold Sun Yongsheng acquired a doctorate in mining science six years ago, he has