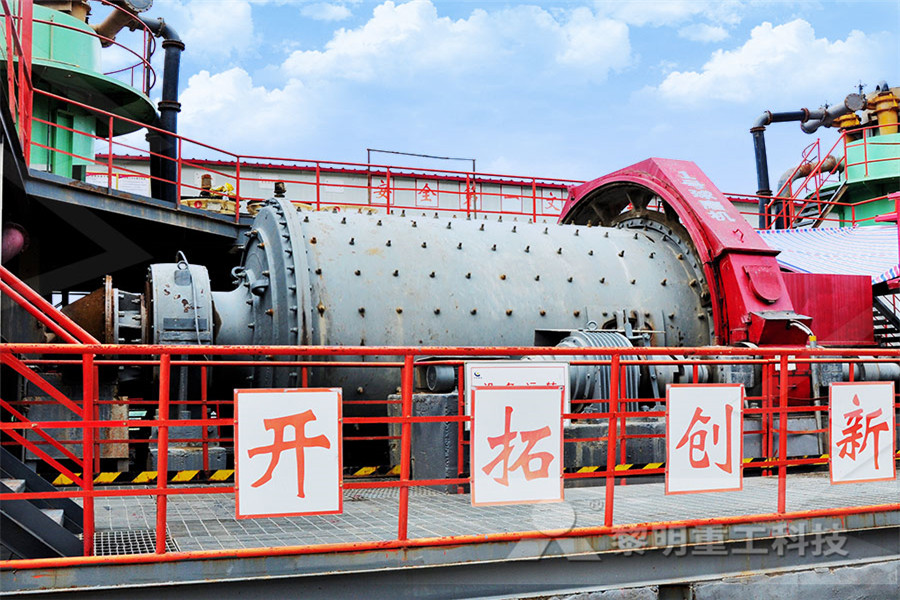

Cement Grinding Unit Cement Grinding Plant EPC Project

Cement grinding unit, or called cement grinding plant, is an individual grinding plant in the finished cement productionThe newtype cement grinding units adopt pregrinding technology The cement grinding units not only reduce the particles of feeding materials, but also help to produce cracks and flaws inside the particles, which largely increase production capacity of cement mill, reduce Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous and super fine (30004000 Blain) cement Grinding operation is monitored for following parameters to ensure objectivity and economy of operation Grinding Operation Objectives and KPIsCement Grinding Cement Plant OptimizationThe cement grinding aids is additional material in liquid or solid form, admixed in small amount during the cement clinker grinding process which can significantly improve the grinding efficiency and reduce energy consumption, without compromising the Cement Grinding Aids Penta Chem

Concrete Grinding for Greater Toronto Floor Grinding

Concrete grinding and leveling is a process used to prepare raw concrete for other flooring alternatives, such as laminate or tiles Grinding can also be used to smooth down rough concrete surfaces to create a more flat, even, and smooth surface The floor is prepared by grinding and leveling the concrete by shaving and scarifying fractions of The process variables in cement grinding process using VRM are strongly nonlinear and having large time delay characteristics also dynamics changes within 24 minutes The fast dynamics necessitate closer attention to the process condition and taking corrective action in time In this paper, the various conventional and modern control strategiesPROCESS CONTROL FOR CEMENT GRINDING IN Cement grinding system Various materials are quantitatively given in the cement batching process according to the set ratio After the materials are discharged proportionally by the feeding metering equipment, they are sent to the ball mill by belt conveyorcement grinding station CHAENG

Cement Mill Cement Grinding Machine AGICO Cement

Cement grinding mill is usually used in the clinker grinding processIt is the final stage in cement production which will directly affect the cement product quality, output and benefits Clinker particles, gypsum, and other materials in cement grinding machine will be ground together into fine powder to match the fineness of the finished productA cement grinder unit, often known as a cement grinding plant, is a standalone grinding mill used in the manufacturing of finished cement Pregrinding technology is used in the new cement grinding facilities The cement grinding units not only decrease the particles of the feeding materials but also aid to generate cracks and defects within Project Report For Cement Grinding Unit Sharda Associates Regardless of a variety of handy concrete cutting tools, an angle grinder is a highly beneficial device to grind the concrete Concrete grinders bring a smooth and clean look on the concrete right away By gaining the expertise on How to Grind Concrete with Angle Grinder, an individual can essentially make an apparently hard task simple There How to Grind Concrete with Angle Grinder 2021 Step by

Rain Cements completes grinding expansion project

Rain Cements completes grinding expansion project 15 October 2021 India’s Rain Cements (Rain Industries) has completed a capacity expansion at its cement mill in Boincheruvupalli village, Kurnool District, Andhra Pradesh The unit’s cement grinding capacity has now been increased from 2033Mta to 2795Mta Published under Cement NewsConcrete grinding and leveling is a process used to prepare raw concrete for other flooring alternatives, such as laminate or tiles Grinding can also be used to smooth down rough concrete surfaces to create a more flat, even, and smooth surface The floor is prepared by grinding and leveling the concrete by shaving and scarifying fractions of Concrete Grinding for Greater Toronto Floor Grinding Cement grinding mill is usually used in the clinker grinding processIt is the final stage in cement production which will directly affect the cement product quality, output and benefits Clinker particles, gypsum, and other materials in cement grinding machine will be ground together into fine powder to match the fineness of the finished productCement Mill Cement Grinding Machine AGICO Cement

Cement Grinding Cement Plant Optimization

Highly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous and super fine (30004000 Blain) cement Grinding operation is monitored for following parameters to ensure objectivity and economy of operation Grinding Operation Objectives and KPIs The raw mix is fed into a circular storage unit called a raw mix storage Then, the mix is extracted transversely from the stockpile by reclaimers and conveyed to a raw mill bin called the raw mix bin for grinding The other raw materials that are used Manufacturing process Lafarge Cement, concrete Concrete grinding cost depends on the area you are working on and the geographical location of course Source: homeguide Usually, it may cost you around 3$ to 12$ per square foot to polish concrete Usually, the cost of dry grinding of concrete is more expensive On the other hand, wet grinding of concrete is cheaperHow to Concrete Grinding [3 Methods,11 Steps,Cost

Grinding Process and Operation PDF Cement Mill

The grinding process and mill operation Progress is our tradition MPS vertical roller mill MVR vertical roller mill TP/ Ne 08 / 04 PFEIFFER Vertical roller mills for the cement industry GEBR PFEIFFER Unchanged Changed / Improved Regardless of a variety of handy concrete cutting tools, an angle grinder is a highly beneficial device to grind the concrete Concrete grinders bring a smooth and clean look on the concrete right away By gaining the expertise on How to Grind Concrete with Angle Grinder, an individual can essentially make an apparently hard task simple There How to Grind Concrete with Angle Grinder 2021 Step by Cement Plant Process Equipment Clinker Grinding Unit Manufacturers Clinker Grinding Units : Ashoka Group supplies a cement grinding unit with each of its cement plant Grinding units can also be supplied separately for other cement plants We supply grinding units upto 2000 TPD plants, capable of handling all types of cementcement plant equipments manufacturer and suppliers of

Cement Manufacturing Process Phases Flow Chart

Cement Manufacturing Process Phase 1: Raw Material Extraction Cement uses raw materials that cover calcium, silicon, iron and aluminum Such raw materials are limestone, clay and sand Limestone is for calcium It is combined with much smaller Mangalam Cement is planning to expand its cement capacity of its Morak cement unit in Ramganj Mandi in Kota district of Rajasthan The project cost is estimated at Rs 2865 million The project involves expanding its cement unit from 17 mtpa to 23 mtpa, grinding capacity from 13 mtpa to 17 mtpa The plant uses dry process technology with Rajasthan Cement Projects Cement IndustryHighly energy intensive unit operation of size reduction in cement industry is intended to provide a homogeneous and super fine (30004000 Blain) cement Grinding operation is monitored for following parameters to ensure objectivity and economy of operation Grinding Operation Objectives and KPIsCement Grinding Cement Plant Optimization

Cement Grinding Aids Penta Chem

The cement grinding aids is additional material in liquid or solid form, admixed in small amount during the cement clinker grinding process which can significantly improve the grinding efficiency and reduce energy consumption, without compromising the Cement grinding station introduction Cement grinding station is a production unit of cement finished products, which doesn't include the last finished stage of the cement production process Cement clinker and the right amount of mixing material China Cement Grinding StationPrice Preference and The grinding process and mill operation Progress is our tradition MPS vertical roller mill MVR vertical roller mill TP/ Ne 08 / 04 PFEIFFER Vertical roller mills for the cement industry GEBR PFEIFFER Unchanged Changed / ImprovedGrinding Process and Operation PDF Cement Mill

CEMENT GRINDING UNIT (20 MTPA) JP PowerVentures

Pradesh state having adjacent Cement Grinding Unit of 40 MTPA Geographically, it is located at Latitude 24°10’17” North and Longitude 81°54’36” East UnitI of Jaypee Nigrie Super Thermal Power Plant Commissioned in September 2014 and UnitII got commissioned in March 2015 respectively Two nos of Boilers based on super Concrete grinding cost depends on the area you are working on and the geographical location of course Source: homeguide Usually, it may cost you around 3$ to 12$ per square foot to polish concrete Usually, the cost of dry grinding of concrete is more expensive On the other hand, wet grinding of concrete is cheaperHow to Concrete Grinding [3 Methods,11 Steps,Cost Regardless of a variety of handy concrete cutting tools, an angle grinder is a highly beneficial device to grind the concrete Concrete grinders bring a smooth and clean look on the concrete right away By gaining the expertise on How to Grind Concrete with Angle Grinder, an individual can essentially make an apparently hard task simple There How to Grind Concrete with Angle Grinder 2021 Step by

Cement Manufacturing Process Phases Flow Chart

Cement Manufacturing Process Phase 1: Raw Material Extraction Cement uses raw materials that cover calcium, silicon, iron and aluminum Such raw materials are limestone, clay and sand Limestone is for calcium It is combined with much smaller the grinding plant settings to ensure the final cement production and quality, from the cement composition to the target silo Autostart The main steps of the automatic startup sequence (mentioned above) can be described as follows: Start of the hydraulic pressure unit and the lubrication system Start of the cement transportÉric Edet, Product Manager, Fives FCB, France, uses the Understanding How The Indian Cement Industry Works In this post, Ashwini Damani Pradeep Jaiswal write on how cement industry in india works what should be the parameters while analyzing any cement company Ashwini is a chartered accountant CFA He has worked with Lafarge, one of the largest cement players in India for more than 6 yearsUnderstanding How The Indian Cement Industry Works