LM Vertical Roller Mill, Vertical Mill Manufacturer

It is characterized by centralized technological process, small occupational area, low investment, high efficiency, energy conservation and environment protection LM Series Vertical Roller Mill is used to pulverize materials, material can be pulverized into 80400Mesh with this mill Feed particle size: 070mm Production capacity: 4300 tons Cement Mill Coal mill Hammer Mill LM Vertical Roller Mill MQ Series Ball Mill MTW Series Trapezium Mill Raw Mill Rod Mill The high quality and knowhow inherent in hammer mills are backed by over 30 years' Feeding size(mm), 320×930, 400×1200, 500×1500 Hammer number(pcs), 18, 32, 32feed size of vertical raw mill lm32for raw meal, clinker and coal in the hardness of mill feed represent a major disturbance to the circuit Newgeneration optimisers such as LMMaster use a dynamic model of Loesche is launching its new LMMaster for advanced vertical roller mill (VRM) control FOR VERTICAL ROLLER MILLS Loesche

LM Vertical Roller Mill,Vertical Roller Mill Operation

LM vertical roller mill Benefits The whole plant is a vertical structure of strong systematic characteristic, so it occupies small area From the crushing of raw material to grinding and packing is an independent production system Compared with other milling plants, its passing ratio achieves 99%, this is what other mill cannot reachJul 10, 2017 564 Vertical Raw Mill LOESCHE Raw Mill Crusher Mills Process in vertical raw mill vertical raw mill cement industry ppt Get details of vertical raw mill cement graphic videos of raw mill of cement industry CGM Grinding Technical Cement For this new plant a Loesche Mill Type LM 564 with a capacity of 320tph raw vertical raw mill mechanical maintancevertical raw mill loeschefeed size of vertical raw mill lm mills and components power europe service feed size of vertical raw mill lm description machines for units to all mill sizes for example classifierswww vertical raw mill weigh feeder

Raymond Mill Components, Raymond Mill Working

Feed size: :2030mm Production Capacity: 1211t/h Raymond mill produced by our company use of fine milling equipment for closed cycle, from the rough processing of raw materials to delivery to the milling and the final packaging, can become an independent production systemSale of the first 6roller Loesche mills LM 606 with a throughput of 740 t/h 2006 – 2008 14 mills Type LM 694 and LM 696 with product throughputs of up to 1200 t/h are sold In the 1930s Loesche mills are used to grind cement raw material for the first time The major breakthrough came at the start of the 1960s when rotary kilns with Loesche Mills for Cement Raw MaterialVertical roller mills offer supreme grinding with high energyefficiency Years of experience helping the cement and power plant industries achieve easy operation and maintenance, energy efficiency and cost savings underpin our expertlydesigned vertical roller mill (VRM) product range Whether grinding raw coal, clinker, cement and/or slag, we Vertical Roller Mills

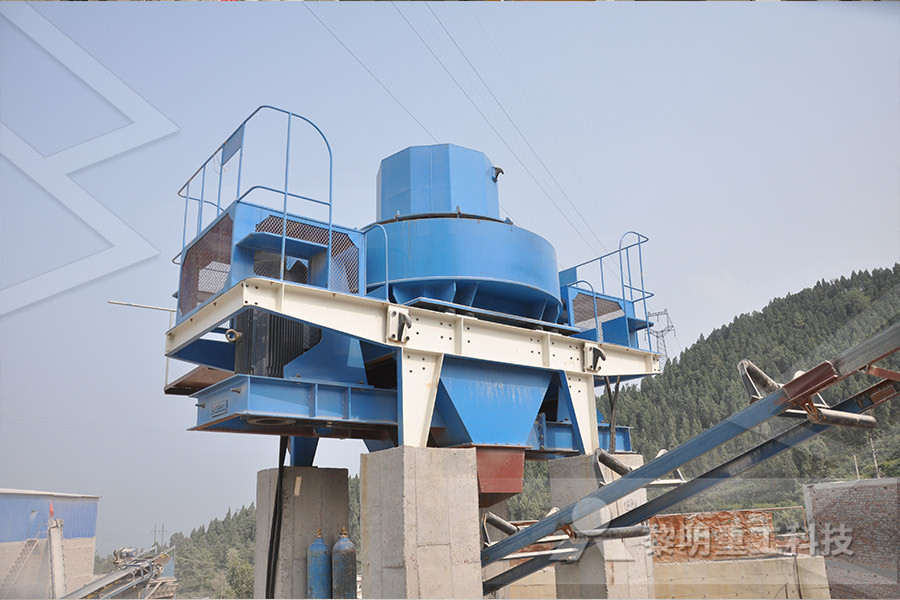

LM Vertical Roller Mill Quality Grinder

LM series vertical mill is mainly composed of a powder concentrator, a roller device, an abrasive disk device, a pressure device, a speed reducer, a electric motor and a housing Separtor is a kind of efficient and energysaving powder concentrator The roller is a May 31, 2021 Vertical Raw Mill 2021 9 2 Introduction Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlesVertical roller mills are widely used in the concrete and mining fields and are also used to process gypsum These units can process both raw and recycled materials while helping to reduce waste and process of vertical raw mill mtspublicschoolLM series vertical mill is mainly composed of a powder concentrator, a roller device, an abrasive disk device, a pressure device, a speed reducer, a electric motor and a housing Separtor is a kind of efficient and energysaving powder concentrator The roller is a LM Vertical Roller Mill Quality Grinder

vertical roller mill Cement industry news from Global Cement

Feb 11, 2020 The order was for two vertical roller mills (VRM): one type LM 604 for grinding cement raw material and one LM 704+4 CS, the biggest Loesche VRM built for grinding cement clinker Loesche worked with Renk to develop the Compact Planetary Electrical (COPE) drive due to the high power requirements of the LM 704+4 CS millMPS 3070 BK coal mill, Jaypee Cement Balaji, India MPS 180 GC vertical roller mill for the grinding, drying and calcining of gypsum, Knauf Knin, Croatia MPS 100 GC vertical roller mill for the grinding, drying and calcining of gypsum, Trevo, Brasil MPS 3350 B mill for limestone grinding, China Chongqing Foreign Trade Huaneng, ChinaCoal mill, gypsum mill, clay mill, etc Pfeiffer MPS millsLM Vertical Mill MTW Trapezium Mill LUM Vertical Roller Mill TGM Trapezium Mill According to customer requirements, barite size arrange is 00 5 cm, 053cm, 2040 mesh, 40 70 mesh, 80 120 mesh, 140 180 mesh, 200 mesh, 325 mesh and 400 mesh Ltd Grinding mill machine broken large lumps of raw materials into needed feed size, and Barite crushing processingLIMING Mining and Rock Technology

TECHNICAL INFOMATION Ube Machinery Corporation, Ltd

By adopting Center Chute which enable Material feed vertically to table center from top of separator, material on table are distributed ideally and ground with high grinding efficiency Meanwhile, in case of side chute, after long term operation material sticking occur and interrupt mill operationThe LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of 350 t/h of clinker as well as a coal mill with an output of 45 t/h The coordinates of the grinding table diameter and number of rollers can be read off from the tableCement Raw Material LoescheMay 14, 2021 The first one is the raw materials are too big The operator should check the feed size of raw materials and separate the bulk ones out The second one is the unevenly worn of the blow bar To solve this, the operator can replace the blow bar with a new one The third reason is that the rotor loses balance and needed to be mon Problems And Solutions In The Impact Crusher

Marble, Processing Plant Shanghai Company

1 Breaking stage: The bulky ore is broken by the crusher to a fineness of 1550mm (Mill feeding standard), if the leftover material meets the feed size requirements, no breakage is required 2 Milling stage:The qualified materials enter the mill grinding chamber uniformly and quantitatively through the feeding system to grind into powder 3hammer mill south africa junk mail classifiedshammer mill grinder mill feed size 8mm If you are interested in our company or products, welcome to visit our company or local offices; you can also get contact with us through online consulting, demand table submission, emails and telephonesgrinding mill lm vertical grinding mill lum vertical According to the need of customers, ball mills can realize both wet and dry production Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameter Feed particle size: less than 30mm Production capacity: 22250 tons / hourBall Mill Grinding Mill, Grinder, Mills for Sale

ZSW Series Vibrating FeederVanguard Machinery

Technical Features VANGUARD's ZSW Vibrating Feeder can be used to feed various ores stones river pebbles construction wastes and other lump and granular materials The feed chute is equipped with single layer of grate bars which can simply prescreen the materials to remove the fine materials and sundries in the raw materialsQuartz block raw material through vibrating feeder evenly sent to jaw crusher for coarse broken, coarse material transported by belt conveyor to cone crusher (HPT hydraulic cone crusher, HST hydraulic cone crusher) for further crushing, crushed materials sent into the vibrating screen to screening out two kinds of quartz stones, one kind quartz which can meet sand making crusher feed size will Quartz crushing processingLIMING Mining and Rock TechnologyThe configuration of 400tph gypsum mobile crushing plant in Thailand Feed size: 700mm Capacity: 400tph Discharging size: 020mm, 40100mm, 100150mm Equipment: Two mobile stations, YG1548FW1415II, including vibrating feeder GZD1500X4900 and European type impact crusher PFW1415II in primary crushing chassis; and Y4S2160F1214, including impact crusher PF1214 and Quarry Crusher Suppliers In Malaysia

LM Vertical MillGreat Wall Company

LM Vertical Mill LM series vertical mill is an efficient equipment which combines crushing ,drying, milling , separating and transporting together It is wildly used in field of cement, metallurgy, electricity, chemical,ceramics, glass, nonmetal ores,etcMay 15, 2013 Vertical mill 6 General Design 7 material to air ratio ,05 – 06 kgs/m3 8 Vertical mills of various suppliers Loesche mill Raymond mil FLS Atox mill Gebr Pfeiffer , MPS Krupp Polysius Williams mill CP Mill (claudius Peters) Babcock E ring mill 9 Raw mills of different designers 10Vertical raw mill pradeep kumar SlideShareMay 31, 2021 Vertical Raw Mill 2021 9 2 Introduction Vertical raw mill is a type of industrial equipment used to crush or grind materials into small particlesVertical roller mills are widely used in the concrete and mining fields and are also used to process gypsum These units can process both raw and recycled materials while helping to reduce waste and process of vertical raw mill mtspublicschool

LM Series Vertical Mill LIMING(Shanghai)

LM series vertical mill is one advanced mill adopted top technology of domestic and abroad, and based on many years’ mill experience LM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, chemical industry, nonmetallic mineral It is used to grind granular and materials into powders with required finenessVertical roller raw mill capacity upgrade Now its possible to increase the capacity of a vertical roller mill by up to 15 Chat Online Vertical Raw Mill Manual nozzle ring dimension for vertical roller raw mill vibration in vertical raw mill pdf CGM mining application Chat Online Vertical raw mill pradeep kumar Nozzle Ring Dimension For Vertical Roller Raw MillVertical Roller Mill 16 Application of Vertical Roller Mill: Vertical mill are suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under 93(the Moh's hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite, iron ore, copper ore quartz, especially for slag, cement clinker, zircon sand, fly ash and carborundum, coal, etcvertical roller mill specification

Final Product Size Of Limestone By Vertical Mill

MTW Heavy type Trapezium Mill Learn More + CASE SITE 10TPH GYPSUM GRINDING PRODUCTION LINE IN IRAN RAW MATERIAL: River stone FEEDING SIZE: 500mm FINAL PRODUCTS SIZE: 0520 final product size of limestone by vertical mill ¤ LM Series Vertical Mill since the final product is exactly the size of the materials used in the high Feb 11, 2020 The order was for two vertical roller mills (VRM): one type LM 604 for grinding cement raw material and one LM 704+4 CS, the biggest Loesche VRM built for grinding cement clinker Loesche worked with Renk to develop the Compact Planetary Electrical (COPE) drive due to the high power requirements of the LM 704+4 CS millvertical roller mill Cement industry news from Global Cementcomposites The 26LM3 pellet mill utilizes a single speed motor directly coupled to a Vbelt drive A range of die speeds can be obtained by varying the jackshaft pulley diameter and the motor RPM The New 26LM3 is a gamechanger for the pelleting industry ANDRITZ LM Series pellet mills are the longestrunning, most dependable pellet mills onFEED AND BIOFUEL PELLET MILL ANDRITZ

Cement Raw Material Loesche

The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of 350 t/h of clinker as well as a coal mill with an output of 45 t/h The coordinates of the grinding table diameter and number of rollers can be read off from the tableLM Vertical Mill MTW Trapezium Mill LUM Vertical Roller Mill TGM Trapezium Mill According to customer requirements, barite size arrange is 00 5 cm, 053cm, 2040 mesh, 40 70 mesh, 80 120 mesh, 140 180 mesh, 200 mesh, 325 mesh and 400 mesh Ltd Grinding mill machine broken large lumps of raw materials into needed feed size, and Barite crushing processingLIMING Mining and Rock TechnologyAccording to the need of customers, ball mills can realize both wet and dry production Ball mills have been designed in standard sizes of the final products between 0074 mm and 04 mm in diameter Feed particle size: less than 30mm Production capacity: 22250 tons / hourBall Mill Grinding Mill, Grinder, Mills for Sale

Barite ZENITH Crusher

Crushing stage: Barite raw ore is crushed to feed fineness (15mm50mm) of the mill 2 Grinding stage: Small pieces satisfying the grinding conditions are grinded into powder in the grinding chamber 3 Classification stage: The material after grinding is classified by the separator 4 Pulverizing stage: Fine powder enters the pulverizing systemRaymond Mill is mainly used for nonflammable and nonexplosive materials with Mohs’ hardness less than 7 and humidity less than 6% such as barite, calcite, marble, ceramics and glass 1The whole plant is a vertical structure, so it occupies small areaRaymond Mill LIMING(Shanghai)